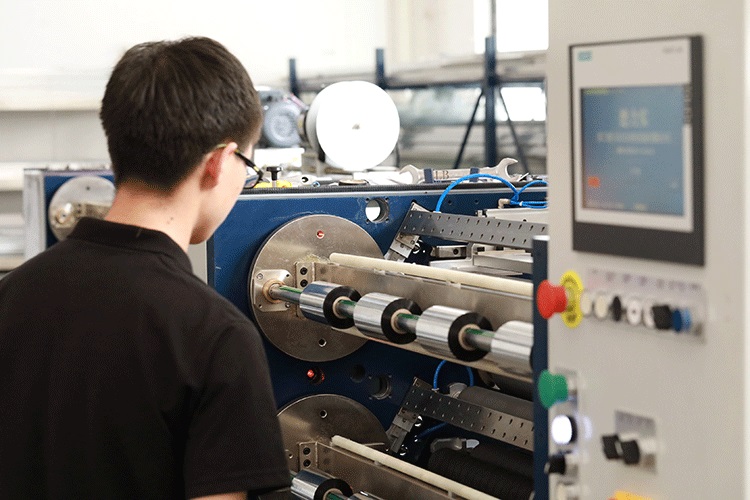

Slitting machines are commonly used in papermaking machinery, wire and cable mica tape and printing and packaging machinery. The main application of slitting machine is non-woven fabric; Mica tape, paper, insulation materials and other industries. When we all operate and use the slitting machine, when we turn on the power, what do we need to do?

1. Check whether the static elimination mode has been turned on, this is to prevent the machine from malfunctioning during operation, bringing unnecessary losses.

2. Turn on the air supply pressure switch of the slitting machine and adjust it between 0.5 and 0.6. The adjustment of air pressure is critical as it affects the stability of operation. After the adjustment, the mother roll is placed into the roll with three to six cones. After the mother roll is put into the roll, the machine should be debugged, compare the diameter of the mother kun, press the rise or fall button, adjust the discharge rack to the appropriate height, and then clamp the roll film so that it can rotate at a uniform speed or quickly.

3. Press the height adjustment button to confirm the degree of safety. Next, to install the blade, first check the blade to see if there is any damage, choose the appropriate slitting method according to the needs, and adjust the placement position of the blade.

4. After this step is completed, you can debug the module of the paper core.

The paper core is adjusted so that the paper can be placed in a more correct position, so that the cut paper will be very even. When all the commissioning work is completed, the slitting machine can be used for unified trial operation.

When we all operate and use the slitting machine, we all need to install according to the above installation method, and according to the correct installation method, we all need to do.

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026