Film slitting machines are used to cut wide film rolls longitudinally into two or more narrow film rolls. Common slitting materials include pressure-sensitive tapes, foams, foils, films, textiles, fabrics, nonwovens, rubber, felt, fiberglass, graphite, cork, and leather, to name a few. There are two main structural forms of slitting and slitting and rewinding, these two slitting methods are very different in their respective application fields, and the choice of which slitting method should depend on the material being cut and your specific slitting requirements.

Film slitting coil cutting machine

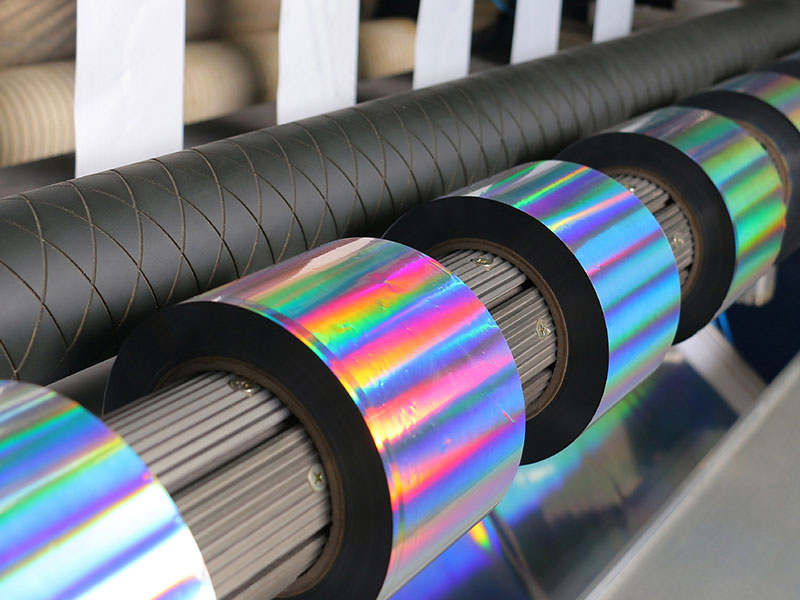

There are many names for coil cutting machine, such as coil cutting machine, single knife slitting machine, slicing machine, film cutting machine, etc., a computer-controlled coiling machine can be suitable for high-efficiency and high-output slitting applications. The use process of the coil cutting machine is like cutting logs, and there is no need for the process of unwinding and rewinding. A large round blade is applied to the coil to cut the parent coil to the desired width. The coil cutter is ideal for slitting all types of materials such as double-sided tapes, self-adhesive tapes, PVC films, and BOPP films. The conventional coil cutting machine includes the main rotation, control system, coil positioning, upper knife positioning, round knife angle adjustment, roll changing shaft device, etc., the coil cutting machine is a low-cost investment slitting equipment, the installation and setting is simple and easy to adjust, the single knife cutting speed is very fast, and even one person can complete the whole film slitting process, which greatly reduces labor costs.

Film slitting rewinder

The film rewinding and slitter machine has an unwinding station to hold the parent roll material, which is unrolled by one or more rollers, and then rewound onto the recycled core by a series of parallel slitting blades that are cut into narrow strips of the required width. The rewinding and slitting machines produced by Delish Machinery can be configured according to the needs of the respective working conditions and budget. For example, single-shaft winding or double-shaft winding can be selected for winding, and the double-shaft design of the turret type can be used to load and unload the finished film roll without affecting the winding operation. In addition, there is a choice between an inflatable shaft or a differential shaft winding shaft, which transmits the torque of the winding tube for constant tension winding, which is particularly critical when the material thickness changes. Depending on the requirements, the slitter rewinder can also be equipped with a variety of slitting methods, including razor slitting, round knife shearing and round knife press cutting.

Advantages of film slitting rewinder:

The rewinding and slitting machine still has many advantages compared with the coil cutting machine. First of all, the slitting rewinder can cut multiple finished rolls at the same time and rewind them onto different paper cores. Secondly, the slitter rewinder can not only cut the film into narrower materials, but also join one roll of material to another roll of material and rewind it into a large roll. Thirdly, the slitting rewinder contains many automatic control systems, including tension feedback control, guide correction control and so on. Delish Machinery can manufacture various types of film slitting machines according to your needs.

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026

Among them, slitting effect, winding quality and tension control are the three core elements that determine the yield.

26. February, 2026

traditional slitting equipment has become difficult to meet the market's stringent needs for efficiency, precision, and flexibility.

26. February, 2026

choosing a professional PET film slitting machine is no longer a luxury option but a necessity to remain competitive.

06. February, 2026