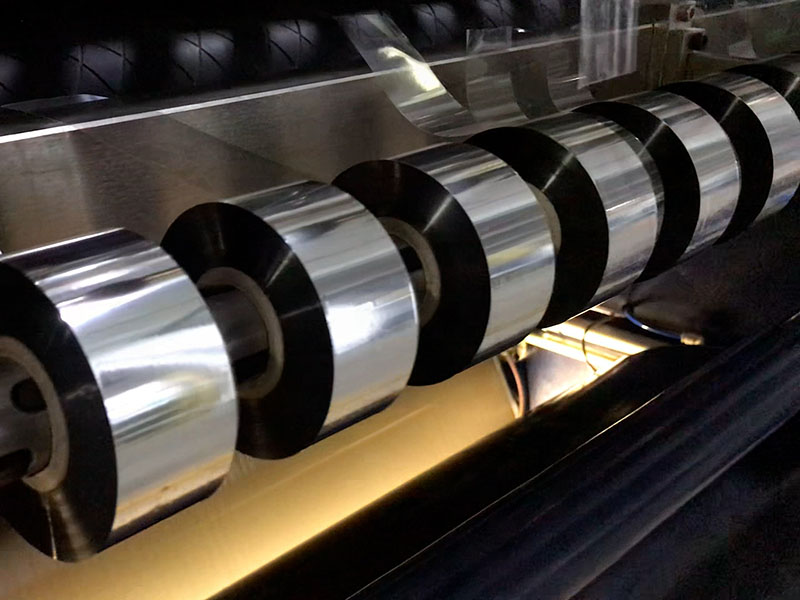

The slitting machine is a prepress that slits a large roll of paper, film, mica tape and other thin materials into small rolls of different widths, and is often used in papermaking machinery and printing and packaging machinery.

The traditional control scheme of the slitting machine is to use a large motor to drive the shaft of rewinding and unwinding, and a magnetic particle clutch is added to the rewinding and unwinding shaft, and the resistance generated by it is controlled by adjusting the current of the magnetic particle clutch to control the tension on the surface of the material.

The slitting machine can be used for stepless speed regulation from zero to synchronous speed, and is suitable for high-speed section fine-tuning and small and medium-power speed regulation system. The slitting machine is also used to adjust the torque by adjusting the current to ensure that the tension remains constant during the winding process.

The main feature of the slitting machine is that the magnetic particle clutch is used as a resistance device, which is controlled by the system to output a DC voltage to control the resistance generated by the magnetic particle clutch. The main advantage of the slitter is that it is a passive device that can control small tensions.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026