To reveal to you in the field of material processing equipment manufacturing, those technological innovation and quality benchmark slitting machine manufacturers. These companies not only master the core technology, but also occupy an important position in the market, providing fast and customized slitting solutions for all walks of life.

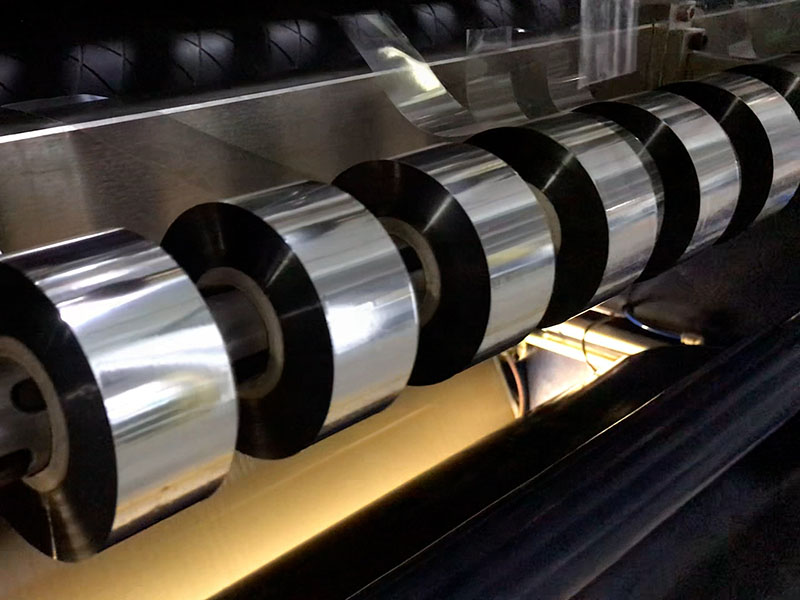

Slitting machine manufacturers, with their deep R&D strength and rich industry experience, continue to launch rewinders, online slitting, composite production lines and other equipment to meet various cutting needs from film, paper to special materials. These devices incorporate smart manufacturing elements to support remote monitoring and data analysis, optimize production processes, and reduce operating costs.

In the highly competitive market environment, some emerging slitting machine manufacturers have also emerged with innovative technology and excellent cost performance, and have won high recognition from the market by focusing on user experience and service. These brands frequently appear on the praise list and voting list, reflecting the continuous demand for good quality slitting machines in the market.

To sum up, the strength of slitting machine manufacturers is to promote the entire industry to a smarter, more environmentally friendly and faster direction with cutting-edge technology research and development, strict quality control and a deep understanding of customer needs. Whether it is an industry giant or a cutting-edge force, they are constantly exploring, committed to providing excellent slitting solutions for global customers, and empowering the transformation and upgrading of the manufacturing industry.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026