In the rapid development of the packaging and paper industry, the innovation of slitting machine technology has become a key force to promote the efficient upgrading of the industry. With the transformation of market demand to personalized and high-quality, advanced slitting machine technology not only improves cutting accuracy and speed, but also brings revolutionary changes to the production process through intelligent and automated integration.

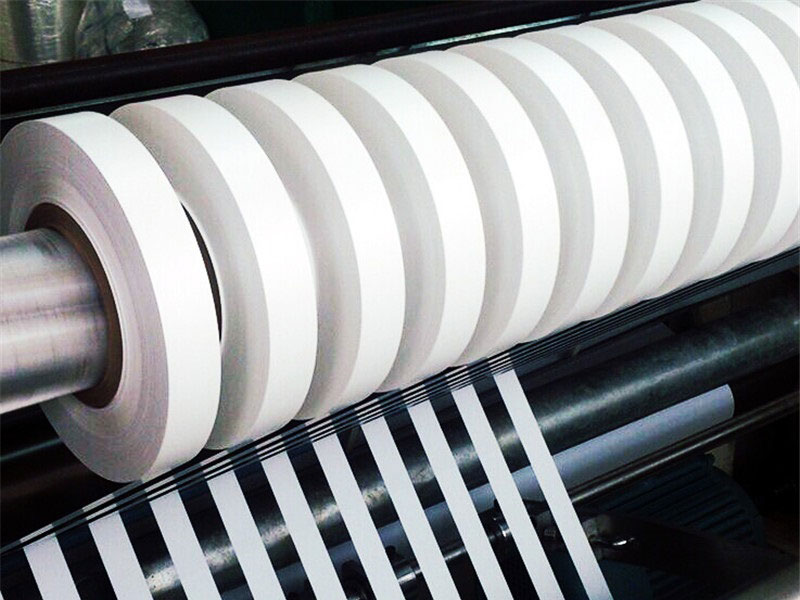

The new slitting machine adopts a servo control system to achieve accurate cutting of various materials, whether it is soft film or heavy cardboard, it can be done exactly right, which greatly reduces material waste and improves the yield rate. This is undoubtedly a powerful tool for packaging and paper companies that pursue zero-defect production to enhance market competitiveness.

Intelligent upgrades to the slitter, such as automatic tool adjustment, material identification and tracking systems, not only simplify the operation process, but also significantly enhance the flexibility and responsiveness of production, allowing enterprises to quickly adapt to the changing needs of the market.

More importantly, the innovation of slitter technology also focuses on energy saving, emission reduction and sustainable development. Modern slitters are designed with a focus on energy efficiency optimization, reducing energy consumption and a waste recycling system to help create a green production environment. These advances are not only in line with the standards, but also a manifestation of corporate social responsibility, promoting the transformation of the entire industrial chain to green and low-carbon.

In short, the continuous innovation of slitting machine technology is not only the direct driving force for the upgrading of the packaging and paper industry, but also a key part of realizing intelligent manufacturing and green development. Through continuous technological breakthroughs and application expansion, slitting machines are helping the industry move towards a more efficient and intelligent future.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026