The rewinder is generally used for the rewinding and slitting of mica tape, paper and film, and plays the role of everything in two, and is often used to cut wide coils. With the development of technology, the application of rewinding machine is becoming more and more extensive. In order to better operate the rewinder, we hope that everyone will keep in mind the safe operation of the rewinder.

1. Before starting the machine, it is necessary to comprehensively check whether all places are safe, including whether the motor, instrument and compressed air are in standby mode, and then confirm these before turning on the machine.

2. When the machine is turned on, a signal should be sent out to start the motor to operate normally before it can operate normally. When starting the rewinder, the speed should be increased from slow to fast, and the speed should be strictly controlled within a certain range.

3. The upper paper core should be tight and reliable, neat and firm, and check whether the round knife is tightly locked and the paper is cut neatly.

4. It is strictly forbidden to have someone in front of the paper roller during work to prevent the running roller from hurting people. When the paper roller is rolled to a certain diameter, do not continue to roll to prevent wrong and broken chains.

5. The staff should operate safely on both sides to adjust the pressure on both sides and the width of the paper edge.

6. If there are special circumstances that need to adjust the round knife to cut the paper, the speed should be put to a very low speed, stop the machine if necessary, it is strictly forbidden to reach out when the equipment is running, the human body can not be close to the running part, in the rewinding process, if the middle round knife is loose or beating can not be slit, it is strictly forbidden for the equipment to pierce the paper with fingers during operation, so as not to hurt the hand.

7. It is strictly forbidden to have people at the place where the paper stick or bracket has not been rewinded.

8. If you find that the roll paper is not tight, it is strictly forbidden to put the paper in it by hand, in order to prevent accidents caused by bringing your hands into the paper sticks.

9. When the paper roller descends, it is necessary to send a signal first, and it can be lowered only after confirming the safety, and after the rewinding is completed, the electromagnetic adjustment switch must be reset to zero, and the motor must be stopped.

10. When the paper roller is unloaded, you must look at whether there is someone in front of the rewinder, whether the paper roller thimble is removed, and send a signal to confirm that it is correct, and then you can get off the roller.

11. When there is a failure in rewinding, it should be shut down and cut off the power supply to avoid hurting people.

12. When starting and lowering the paper roller, a signal must be sent when the roller is lowered, and non-post personnel are prohibited from operating.

The stable operation of the slitting rewinder is the basis for producing high-quality coil products.

10. December, 2025

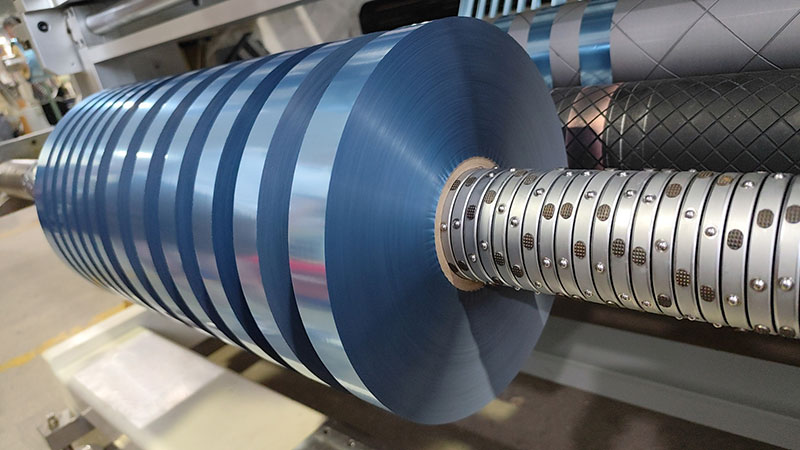

Precisely cut the wide master roll according to the preset dimensions, then rewind it into finished rolls suitable for subsequent processing or direct use.

09. December, 2025

Cut wide rolls of film, paper, nonwoven fabric, metal foil, and other materials to precise sizes, and then rewind them into finished rolls that meet downstream requirements.

09. December, 2025

A slitting rewinder is a device that slices wide coils into multiple narrow strips of material and rewinds them into independent rolls.

09. December, 2025

A suitable slitting and rewinding machine can not only greatly improve production efficiency, but also reduce material loss and ensure product quality.

08. December, 2025