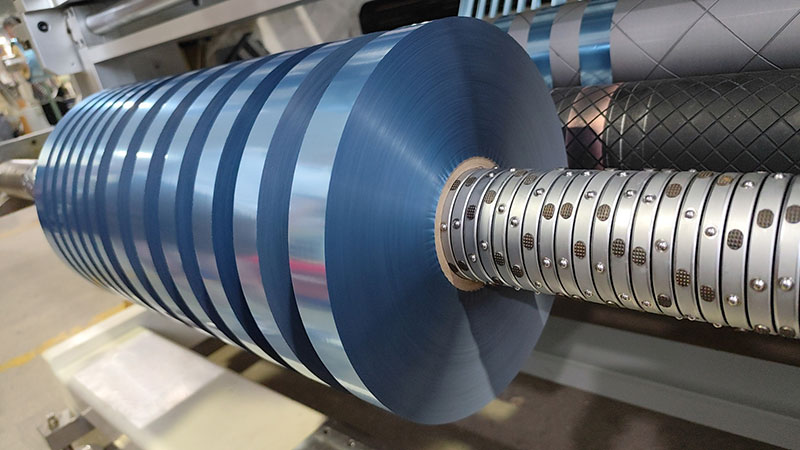

The slitting machine can be adjusted according to different production needs to adapt to the slitting requirements of various materials and products. Through simple settings and parameter adjustments, the slitter is able to flexibly handle materials of various sizes, thicknesses and shapes, increasing the flexibility and diversity of production while ensuring product quality.

As an important equipment in modern industrial production, the slitting machine injects stronger efficiency and quality assurance into the production process with its automated, accurate and flexible characteristics. The slitting machine greatly improves the production efficiency, reduces the labor cost and production cycle, and realizes a high degree of automation of the production process. At the same time, the precise cutting ability and flexibility of the slitter machine have greatly improved the quality and diversity of products.

How can a slitter improve production efficiency and quality? The answer lies in the intelligent control, precise cutting and flexible adjustment of the slitter. By introducing slitting machines, companies are able to achieve a more efficient production process, improve product quality, and stand out from the competition. Let's use the power of slitting machines to bring more efficient industrial production!

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026