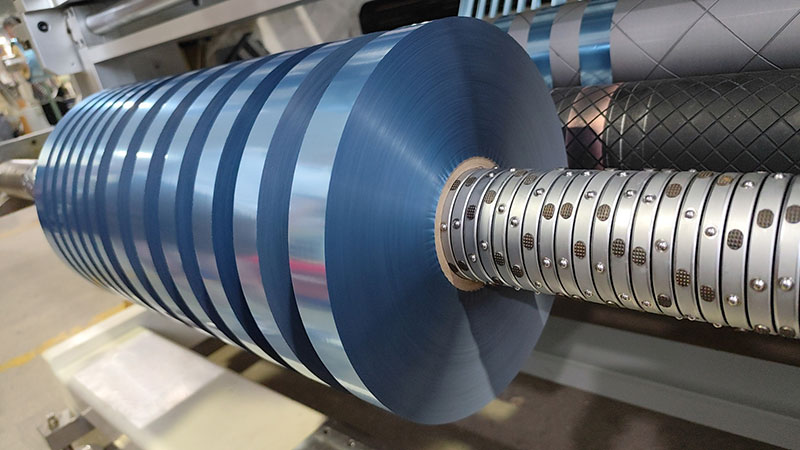

In industrial production, fast and accurate material slitting process is one of the key links to improve the overall production line efficiency. As a representative of advanced technology in modern manufacturing, high-speed slitting machine has shown significant advantages in the slitting processing of paper, film, metal foil, nonwovens and other materials with its excellent performance characteristics.

High-speed and fast

The first feature is "high speed". By adopting advanced drive system and optimized mechanical design, the high-speed slitting machine can achieve higher operating speed than the traditional slitting machine, significantly increasing the material handling per unit time, thereby shortening the production cycle and improving production efficiency.

Precise control

Equipped with a high-precision servo control system and a precise measurement feedback device, the high-speed slitting machine can realize the high-precision control of material slitting. Whether it is a thin film or a thick cardboard, it can achieve small dimensional tolerances and ensure the uniformity and stability of the finished product quality.

Automation and Chemistry

Integrate automatic feeding, slitting, rewinding and other functions in one, reduce manual intervention, reduce labor intensity, and improve operation safety. The control system can realize parameter preset, fault diagnosis, remote monitoring, etc., optimize the production process, and improve response speed and flexibility.

Flexible and adaptable

In the face of diversified product needs, the high-speed slitting machine has good flexibility and adaptability. With quick tool changes and machine parameter adjustments, slitting tasks of different materials, thicknesses and widths can be easily adapted to individual and mass production requirements.

energy conservation

The use of energy-saving motors and optimized power transmission design reduces energy consumption, noise pollution and waste generation, in line with the modern green production concept, and contributes to the sustainable development of the enterprise.

conclusion

To sum up, the high-speed slitting machine with its good performance characteristics, not only greatly improves the production efficiency and product quality, but also reduces the operating cost and the market competitiveness of the enterprise through the design concept of high automation and modernization. In the pursuit of fast, accurate and modern industrial production, high-speed slitting machine is undoubtedly an ideal choice to improve work efficiency and promote the industry.

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026

Among them, slitting effect, winding quality and tension control are the three core elements that determine the yield.

26. February, 2026

traditional slitting equipment has become difficult to meet the market's stringent needs for efficiency, precision, and flexibility.

26. February, 2026

choosing a professional PET film slitting machine is no longer a luxury option but a necessity to remain competitive.

06. February, 2026