In modern manufacturing, as a key processing equipment, the performance of the slitting machine directly affects the efficiency and quality of material processing. Good slitter manufacturers continue to expand their product lines to meet the growing demand for handling diverse materials and thicknesses, ensuring that customers can find suitable solutions in complex and changing production environments.

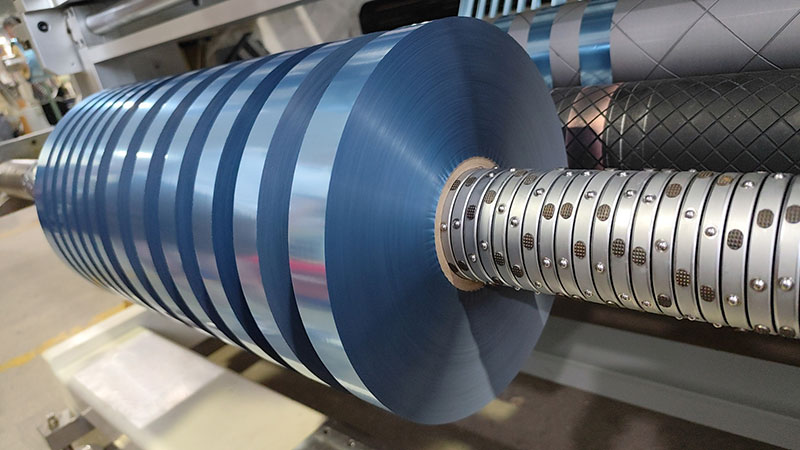

1. Film slitting machine

Specially designed for soft thin materials such as plastic film, composite film, aluminum foil, etc., this kind of slitting machine emphasizes high speed and high precision, adopts a precise guide roller system and automatic tension control to ensure that the material is smooth and wrinkle-free, and the cutting edge is smooth, which is suitable for food packaging, pharmaceutical packaging and other industries.

2. Paper slitting and rewinding machine

For medium-thick materials such as paper, cardboard, wallpaper, etc., slitting machine manufacturers provide rewinding machines with functions such as automatic deviation correction and metering, which can not only complete accurate slitting, but also carry out rapid winding processing, and are widely used in the field of printing and stationery manufacturing.

3. Metal foil slitting machine

For copper foil, aluminum foil and other metal sheet materials, the manufacturer has developed a slitting machine that combines a high-rigidity structure and a cemented carbide cutter to ensure a stable cutting process without burrs, suitable for electronics, battery manufacturing and other industries, and meet the requirements of high precision.

4. Non-woven fabric slitting machine

With the expansion of the market for sanitary products and filter materials, slitting machine manufacturers have also launched rapid slitting equipment for non-woven fabrics, with ultrasonic cutting or round knife cutting technology, to avoid material drawing, keep the cutting edge clean and tidy, and adapt to the rapid production rhythm.

5. Customized solutions

In the face of slitting needs of special materials or unconventional thicknesses, manufacturers provide one-stop customized services from consulting, design to manufacturing, whether it is ultra-thin film or heavy sheets, we can create exclusive slitting solutions for customers to ensure production efficiency and product quality.

Through continuous enrichment of product lines and technological innovation, slitting machine manufacturers not only meet the market's demand for material diversity processing, but also promote the development of the entire industrial chain in a faster and more precise direction, contributing to the transformation of the manufacturing industry.

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026

Among them, slitting effect, winding quality and tension control are the three core elements that determine the yield.

26. February, 2026

traditional slitting equipment has become difficult to meet the market's stringent needs for efficiency, precision, and flexibility.

26. February, 2026