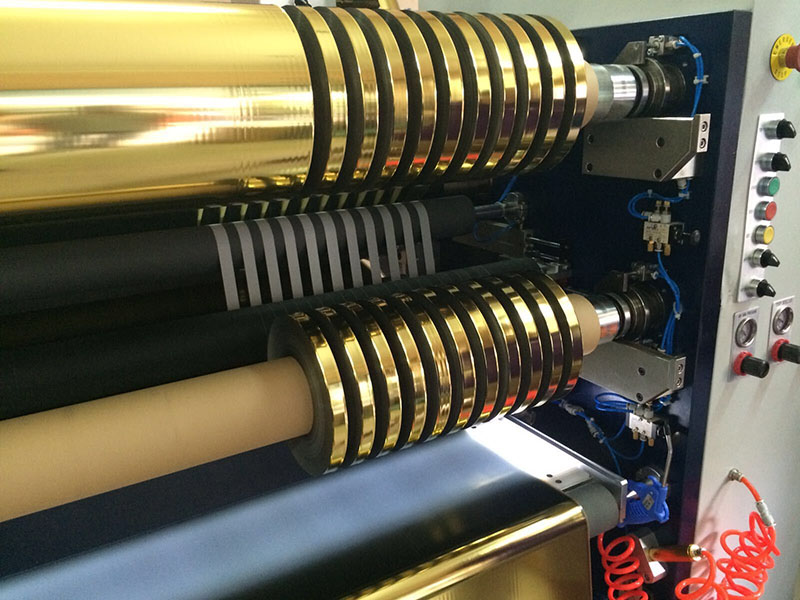

First, the working principle of hot stamping foil slitting and rewinding machine

Hot stamping foil slitting and rewinding machine is a kind of equipment specially used for slitting and repeated winding of hot stamping foil coils, its working principle is mainly to put the hot stamping foil coil on it through the coil positioning device, and send it to the slitting device to carry out longitudinal or transverse slitting of the coil. The slitted hot stamping foil coils are sent to the rewinding unit in turn, and the rewinder of the rewinding unit rewinds them into smaller coils. The entire workflow requires many repetitive movements to complete for efficient slitting and rewinding of hot stamping foil.

Second, the application scenario of hot stamping foil slitting and rewinding machine

Hot stamping foil slitting and rewinding machine has the characteristics of high slitting accuracy, high production efficiency and simple operation, and is widely used in electronics, electrical appliances, communications, food and other fields. In the fields of electronics, electrical appliances and communications, hot stamping foil slitting and rewinding machines can be used to produce key electronic components such as capacitors, inductors, transformers, power supply inductors, etc., and can also be used to produce some special-purpose composite materials.

In the food industry, hot stamping foil slitting and rewinding machine can be used to produce food products such as roll cakes, wraps, breads, biscuits, etc., and can cut roll food into small rolls to meet the needs of different food processing and packaging.

Third, precautions for using hot stamping foil slitting and rewinding machine

1. Before using the hot stamping foil slitting and rewinding machine, it is necessary to conduct a comprehensive inspection and maintenance of the equipment to ensure that all components are operating normally.

2. When using the slitting device for slitting, it needs to be adjusted according to the actual needs to ensure the slitting accuracy and efficiency.

3. When using the rewinding device, it is necessary to clean the receiver and adjust the roller clearance in time to ensure the quality of the coil and the efficiency of the coiling.

4. When carrying out the repair and maintenance of the hot stamping foil slitting and rewinding machine, it is necessary to turn off the power supply and disassemble the relevant parts to avoid accidents such as electric shock.

To sum up, through a detailed introduction to the working principle and application scenarios of hot stamping foil slitting and rewinding machine, we can understand the wide application of the equipment in electronics, electrical appliances, communications, food and other fields, and at the same time, we can also understand the precautions for various parts when using the equipment to ensure the safety and efficiency of the equipment.

this once management pain point is now transforming into a powerful tool for printing enterprises to reduce costs and increase efficiency.

26. February, 2026

This article will delve into how to make the hot foil slitting machine the engine of your production process optimization through scientific equipment selection and management.

26. February, 2026

A precision platform that integrates multifunctional applications with cross-disciplinary process expansion.

26. February, 2026

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026