The working principle of the slitting rewinder mainly involves two processes: cutting and winding of materials.

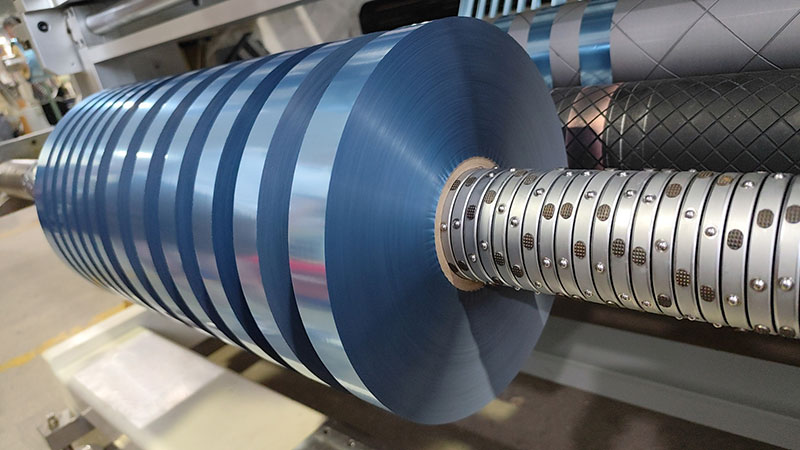

First of all, the slitting rewinder precisely cuts the raw large roll of material by means of a blade on the knife holder. This step usually requires the width of the cut to be determined according to the customer's needs or the specifications of the downstream product. During the cutting process, the blade acts on the material with a certain speed and pressure, which cuts it to the desired width size.

Secondly, the cut material will be guided by the guide rollers to the rewinding section for winding. During the winding process, the slitting rewinder uses a tension control system to ensure that the material maintains the proper tension. This is to avoid slack or too much tension in the material during the winding process, which will affect the quality of the winding and the subsequent processing use.

In addition, the slitting rewinder may also be equipped with an automatic guiding system that detects the deviation of the material in real time and automatically adjusts the position of the guide rollers to ensure that the material remains straight at all times during the winding process.

Finally, the slitted and rewound material is wound into small rolls for subsequent processing, transport or storage. Throughout the process, the slitting rewinder precisely controls and coordinates the individual components through the control system to ensure the smooth progress of the whole process and the quality of the product.

In general, the working principle of the slitting rewinder is to process the original large roll material into the required width of the small roll material through precise cutting and winding operations to meet the diverse needs of customers.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026