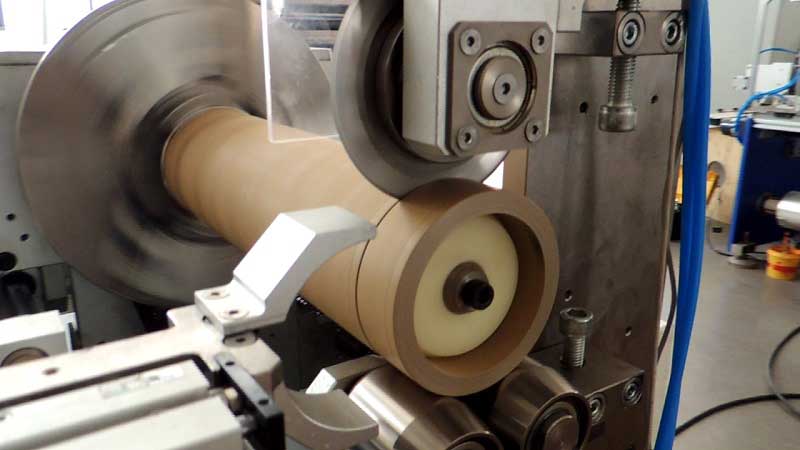

First, the basic principle of the paper tube cutter

Paper tube cutter is a kind of equipment specially used to cut paper tubes, which is mainly composed of a mechanical part and a control part. The mechanical part includes the spindle, cutting tool, positioning device, etc., and the control part includes the electrical control cabinet, PLC program, etc. The working principle of the paper tube cutter is to control the movement of the cutting tool through the control system, and the paper core is cut according to the set size.

Second, the operating regulations of the paper tube cutting machine

1. The operator should be professionally trained before operating the paper cutter independently.

2. Before operation, check whether all parts of the equipment are in good condition and whether the electrical equipment is well grounded.

3. Pay attention to keep your hands clean during operation, and never bring impurities such as oil stains into the work area.

4. Operators should wear labor protection equipment, such as protective glasses, gloves, etc.

5. During the operation, attention should be paid to the operation of the equipment, and the problems should be found and dealt with in time.

6. The operator shall abide by the operating procedures and shall not adjust the equipment parameters without authorization to avoid accidents.

7. After the operation, the equipment should be cleaned and maintained in time to ensure the stable performance of the equipment.

Third, regulations for the safe operation of the paper tube cutting machine

1. When operating the paper tube cutter, it is strictly forbidden to put hands or other objects into the cutter to avoid injury.

2. Do not place tools and other items around the knives during operation, so as not to affect the safety of the operation.

3. During the operation of the paper tube cutter, it is strictly forbidden to engage in other unrelated work, so as not to distract and cause accidents.

4. When the paper tube cutter fails, it should be stopped immediately and the maintenance personnel should be notified for processing.

5. Avoid standing directly in front of the cutter when operating the paper tube cutter to avoid being hit by the rebounding material.

6. Operators should conduct regular safety training to understand the safety operation procedures of the equipment and improve safety awareness.

Fourth, the maintenance specification of the paper tube cutting machine

1. The paper tube cutter should be cleaned regularly during use to keep the equipment clean and hygienic.

2. Lubricating oil should be added regularly during the operation of the equipment to maintain the normal operation of the equipment.

3. The paper tube cutter should be repaired in time when it encounters a fault during use, and a trial run should be carried out after maintenance to ensure that the equipment is normal.

4. During the operation of the paper tube cutter, the equipment should be checked regularly, and the problems should be dealt with in time.

5. The spare parts of the paper tube cutter should be updated and replaced in time to ensure the service life and performance of the equipment.

To sum up, the establishment of the rules and regulations for the operation of the paper tube cutter is of great significance to ensure the safety of operators, improve the service life of the equipment, and improve production efficiency. The operator should strictly abide by the operating procedures, improve safety awareness, effectively maintain the equipment, and ensure the normal operation of the paper tube cutter. Only in this way can we better guarantee the smooth progress of production.

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025