Aluminum foil slitting machine plays a vital role in aluminum foil production, and its applications are wide and critical. The following is a detailed analysis of the application of aluminum foil slitting machine in aluminum foil production:

First, the basic functions of the aluminum foil slitting machine

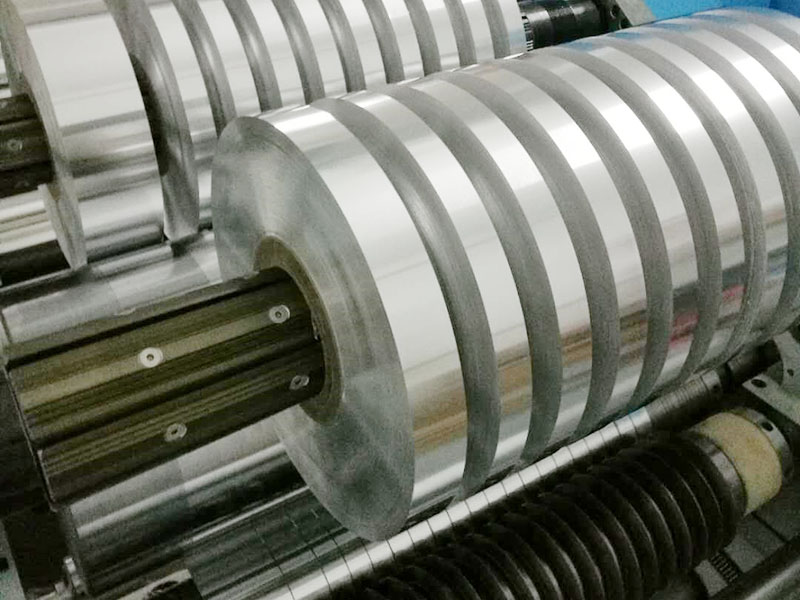

Aluminum foil slitting machine is a kind of mechanical equipment specially used to process aluminum foil materials, and its main function is to cut wide aluminum foil strips into small strips of specific width for further processing or use. In this process, the aluminum foil slitting machine needs to precisely control parameters such as cutting length, speed and tension to ensure that the cut aluminum foil strips have the required width and precision.

Second, the application field of aluminum foil slitting machine

1. Aluminum foil processing: The aluminum foil slitting machine plays a central role in the aluminum foil processing process, which can cut the aluminum foil strip quickly and accurately, improving the production efficiency.

2. Packaging materials: The aluminum foil slitting machine can cut the aluminum foil strip into strips of appropriate width, which is used to make various packaging materials, such as aluminum foil packaging bags, aluminum foil packaging boxes, etc. These packaging materials have good moisture-proof and anti-oxidation effects, which can protect the quality of products and extend the shelf life.

3. Building materials: In the construction field, aluminum foil slitting machine can be used to make various aluminum foil building materials, such as aluminum foil decorative exterior walls, aluminum foil roofs, etc. These materials improve the aesthetics and moisture resistance of buildings.

4. Electronics industry: Aluminum foil slitting machine is also widely used in the electronics industry, such as for the production of circuit boards, connecting wires and other electronic components. Aluminum foil strips have excellent electrical conductivity and corrosion resistance, which can meet the needs of electronic products.

5. Food industry: Aluminum foil slitting machine plays a vital role in the food industry. Aluminum foil material has good properties such as oxygen insulation, moisture resistance, waterproof and fire resistance, which can effectively protect the freshness and quality of food. The aluminum foil material produced by the aluminum foil slitting machine is usually used to make various food packaging bags, food boxes, and beverage packaging, etc.

Third, types and characteristics of aluminum foil slitting machine

1. Type: Aluminum foil slitting machine can be divided into many types according to its different slitting methods and uses, such as manual slitting machine, semi-automatic slitting machine and fully automatic slitting machine, etc. The manual slitting machine is mainly suitable for small batch production, and the operation is simple; The operation of the semi-automatic slitting machine is more convenient and fast, and it can achieve a certain degree of automatic control; The automatic slitting machine has higher production efficiency and precision, and is suitable for mass production.

2. Features: Aluminum foil slitting machine has the advantages of high efficiency, precision and easy operation. The equipment can realize continuous automatic cutting and improve production efficiency. At the same time, due to the use of precision tools, the cutting edge is neat and the precision is high. In addition, the machine is easy to operate, and the cutting can be completed automatically by simply setting the parameters.

Fourth, the tension control of the aluminum foil slitting machine

The tension control of the aluminum foil slitting machine is one of the key factors to ensure the quality of the cut. Tension control refers to the ability to well control the tension of aluminum foil when it is conveyed on the equipment, and this control must be effective for any operating speed of the machine, including acceleration, deceleration and constant speed of the machine. Even in the event of an emergency shutdown, it has the ability to guarantee that the aluminum foil does not break in the slightest. There are basically two kinds of slitting machine tension control: manual tension control and automatic tension control. Manual tension control needs to be controlled by the operator according to the change of the roll diameter during the winding or unwinding process; The automatic tension control is to directly measure the actual tension value of the strip by the tension sensor, and then feedback to the tension controller, calculate the control signal by comparing the preset tension value, and automatically control the execution unit to make the actual tension value equal to the preset tension value.

To sum up, aluminum foil slitting machine has a wide range of applications and plays an important role in aluminum foil production. With the continuous progress of mechanical technology and the continuous expansion of the aluminum foil market, the aluminum foil slitting machine will continue to play a more important role in the aluminum foil processing industry.

This is not only a simple process of turning a wide coil material into a narrow band, but also an ultimate dance of tension, precision and blade on the micron scale.

15. October, 2025

Here are the key technical points of multi-material slitting:

05. August, 2025

When processing aluminized PET film, the slitting machine with insufficient corrosion resistance may corrode the knife roller due to solvent residues, affecting the sealing performance.

05. June, 2025

The following are the core technologies and application solutions of slitting machine in metal foil processing:

09. May, 2025

The following is an in-depth analysis of its core technology, covering the key links of precise slitting and efficiency improvement:

26. March, 2025