The production technology of aluminum foil slitting machine covers many aspects to ensure its performance with high precision, high efficiency and high degree of automation. The following is a detailed summary of the production technology of aluminum foil slitting machine:

1. Mechanical design technology

1. Structural layout: The overall structural layout of the aluminum foil slitting machine needs to be reasonable to ensure the coordinated operation between the various components. This includes the rational layout of the feeding system, cutting system, winding system and electronic control system, as well as the design of the connection between the components and the support structure.

2. Material Selection: In mechanical design, the choice of materials is crucial. The aluminum foil slitting machine needs to choose high-strength, high-wear-resistant, and corrosion-resistant materials to ensure the stability and durability of the equipment.

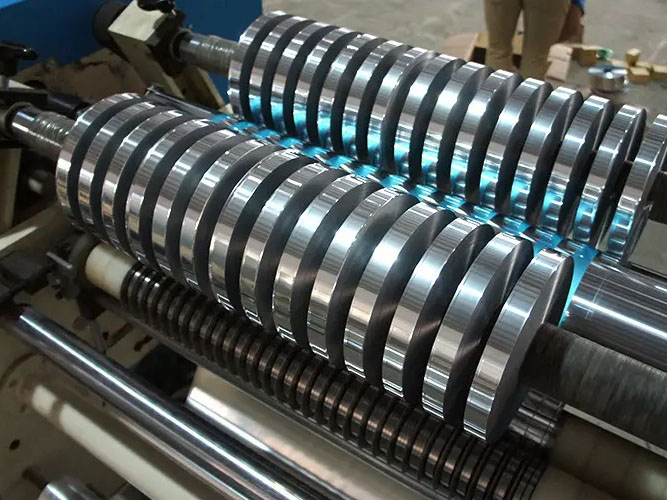

3. Precision machining: The individual parts of the aluminum foil slitting machine need to be precision machined to ensure its dimensional accuracy and shape accuracy. This includes precision machining of key components such as cutting blades, slitting blades, unwinding devices, winding devices, etc.

2. Tension control technology

1. Tension sensor: The aluminum foil slitting machine needs to be equipped with a tension sensor to monitor the tension change of aluminum foil during the conveying process in real time.

2. Tension controller: Through the data fed back by the tension sensor, the tension controller can automatically adjust the actuator to make the actual tension value equal to the preset tension value, so as to achieve the purpose of stabilizing the tension.

3. Automatic compensation function: The unwinding and winding tension of the aluminum foil slitting machine needs to have automatic compensation function, including acceleration and deceleration compensation, inertia compensation and friction compensation to ensure the stability of the tension.

3. Automatic control technology

1. Programmable Controller (PLC): The aluminum foil slitting machine usually uses PLC as the core controller to realize the automatic control of the equipment. The PLC can receive signals from sensors and control the actions of individual actuators according to preset programs.

2. Inverter: Inverter is used to adjust the speed of the motor to achieve precise control of actions such as feeding, cutting and winding of the aluminum foil slitting machine.

3. Touch screen (HMI): Through the touch screen, the operator can easily set parameters, monitor the status of the equipment and receive alarm information, which improves the operability and maintainability of the equipment.

4. Cutting and slitting technology

1. Cutting blades: The cutting blades of aluminum foil slitting machines need to have high hardness, high wear resistance, and high sharpness to ensure the precision and efficiency of cutting.

2. Slitting blades: Slitting blades are used to split the cut aluminum foil material according to the required number and spacing. Its design and manufacture need to take into account factors such as the material, thickness and cutting speed of the aluminum foil.

3. Cutting and slitting accuracy: The cutting and slitting accuracy of the aluminum foil slitting machine is one of the important indicators to measure its performance. High-precision cutting and slitting can be achieved by optimizing the design of the cutting and slitting device and adopting high-precision sensors and controllers.

5. Security protection technology

1. Emergency stop function: The aluminum foil slitting machine needs to be equipped with an emergency stop function, so that it can be stopped quickly in case of abnormal situations and protect the safety of equipment and personnel.

2. Guards: Guards need to be installed in all dangerous parts of the equipment to prevent operators from entering or touching dangerous parts by mistake.

3. Alarm system: The aluminum foil slitting machine needs to be equipped with an alarm system so that it can send an alarm to the operator in time when there is a fault or abnormal situation.

To sum up, the production technology of aluminum foil slitting machine covers many aspects such as mechanical design, tension control, automatic control, cutting and slitting, and safety protection. The comprehensive application of these technologies ensures the high performance, high precision and high reliability of the aluminum foil slitting machine.

This is not only a simple process of turning a wide coil material into a narrow band, but also an ultimate dance of tension, precision and blade on the micron scale.

15. October, 2025

Here are the key technical points of multi-material slitting:

05. August, 2025

When processing aluminized PET film, the slitting machine with insufficient corrosion resistance may corrode the knife roller due to solvent residues, affecting the sealing performance.

05. June, 2025

The following are the core technologies and application solutions of slitting machine in metal foil processing:

09. May, 2025

The following is an in-depth analysis of its core technology, covering the key links of precise slitting and efficiency improvement:

26. March, 2025