The application range of paper tube cutters is not completely limited, but relatively wide, but it does have certain limitations. Here's a detailed analysis of its range of applications:

Wide range of applications

1. Printing industry: The paper tube cutter can cut out plastic tubes or paper tubes suitable for labels, non-woven fabrics, films, tapes, etc., which have a wide range of applications in the printing industry.

2. Packaging industry: Paper or plastic tubes cut by paper tube cutters can be used as packaging materials, such as for fixing, protecting, and displaying products.

3. Leather industry: In the process of making leather products, the paper cutter can provide a support structure to help complete the forming and fixing of leather products.

4. Hardware industry: Hardware products need suitable packaging materials in the process of packaging and transportation, and the paper tubes or plastic tubes cut by the paper tube cutter can meet this demand.

Apply restrictions

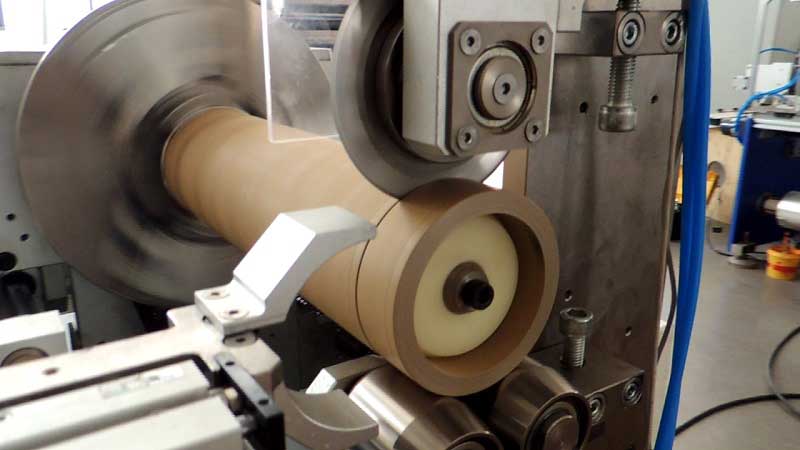

1. Material type: Although the paper tube cutter can cut a variety of materials, such as paper, plastic, etc., it has certain requirements for the hardness and thickness of the material. For materials that are too hard or too thick, a higher level of cutting equipment may be required.

2. Cutting accuracy: Although modern paper cutters already have high cutting accuracy, for some application scenarios that require extremely high precision, such as precision instrument packaging, more precise cutting equipment may be required.

3. Degree of automation: Although the automatic paper tube cutter has greatly improved the production efficiency, in some application scenarios that require a high degree of automation and intelligence, such as continuous cutting operations on large-scale production lines, more advanced automation control systems may be required.

To sum up, the application range of paper tube cutter is relatively wide, but there are also certain limitations. When choosing a paper tube cutter, it is necessary to consider comprehensively according to the specific application scenarios and needs to ensure that the selected equipment can meet the production requirements and improve work efficiency.

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025