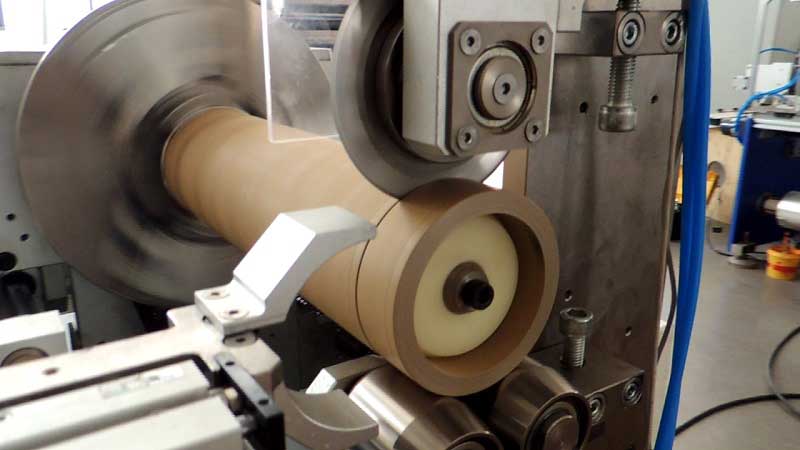

As a professional paper tube cutting equipment, paper tube cutter plays an important role in many industries such as papermaking, printing, and packaging. Here is a detailed introduction to the advantages and disadvantages of the paper tube cutter:

merit

1. Efficient and fast:

• The paper tube cutter adopts an automatic control system, which can complete the cutting task quickly and accurately, and significantly improve the production efficiency.

2. High precision:

• The application of high-precision cutting methods such as laser cutting enables the paper tube cutter to meet the occasions with high requirements for cutting accuracy and ensure the accuracy of cutting size.

3. Wide range of application:

• Paper tube cutter is suitable for cutting paper tubes of various materials, including paper of different thickness and hardness, as well as PE pipes, PVC hoses and other similar materials, with a wide range of applications.

4. Energy saving and environmental protection:

• Adopt advanced energy-saving technology, which can reduce energy consumption and noise pollution, and meet the green production requirements of modern industry.

5. Easy to operate:

• Paper tube cutters are usually equipped with color touch screen and PLC programming control, which makes the operation easier and more intuitive, reducing the difficulty of operation and labor costs.

6. Flexible Adjustment:

• The paper cutter has a large adjustment range, and the cutting length, inner diameter and other parameters can be adjusted according to the actual needs to meet the individual needs of different customers.

shortcoming

1. Higher equipment costs:

• In particular, the cost of equipment is relatively high for paper tube cutters using high-precision cutting methods such as laser cutting, which may increase the investment pressure of enterprises.

2. High technical requirements for operators:

• Although easy to operate, in order to ensure the quality and safety of the cut, the operator needs to have a certain amount of professional knowledge and operational skills.

3. Maintenance Costs:

• The paper tube cutter needs regular maintenance and maintenance during use to ensure the stability and service life of the equipment. This can increase the maintenance cost and time cost of the business.

4. Cutting Noise:

• Although modern tube cutters have improved in terms of noise reduction, they can still produce a certain amount of noise during the cutting process, which can have a certain impact on the working environment and operators.

5. Cutting Material Limitations:

• Although the tube cutter is suitable for cutting a wide range of materials, there may still be some limitations for cutting some special materials or extra-thick materials.

To sum up, the paper tube cutter has the advantages of high efficiency and speed, high precision, wide range of application, energy saving and environmental protection and easy operation, but it also has the disadvantages of high equipment cost, high technical requirements for operators, maintenance costs, cutting noise and cutting material limitations. When choosing a paper tube cutter, enterprises need to comprehensively consider their own needs and actual conditions, and choose the most suitable equipment for themselves.

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025