The technical characteristics of the thermal transfer ribbon slitting machine are mainly reflected in the following aspects:

1. High-precision slitting ability

The thermal transfer ribbon slitting machine has high-precision slitting ability, which can accurately cut the ribbon material into the required width according to the needs of the printed matter specifications. This high-precision slitting ensures the stability and reliability of the ribbon in subsequent use, and avoids print quality problems caused by width deviations.

2. Automation and intelligent control

1. Automatic operation: The thermal transfer ribbon slitting machine usually adopts an automatic control system, which can realize the functions of automatic feeding, automatic cutting and automatic receiving. This reduces manual intervention and errors, increasing productivity.

2. Intelligent adjustment: Some thermal transfer ribbon slitting machines are also equipped with an intelligent adjustment system, which can automatically adjust the slitting parameters according to the characteristics of the material and the slitting requirements, such as cutting speed, cutting pressure, etc. This further improves the accuracy and stability of the slitting.

3. Tension control system

The thermal transfer ribbon slitting machine is equipped with a high-precision tension control system, which can ensure that the material maintains a stable tension during the slitting process. Excessive tension may cause the ribbon base film to be stretched and damaged, and if the tension is insufficient, it is easy to wrinkle or print white lines and other problems. Therefore, the tension control system is essential to ensure the quality of the slitting and the printing results.

4. Versatility and flexibility

1. A variety of material processing: The thermal transfer ribbon slitting machine can handle a variety of ribbon materials including wax base, resin base and mixed base to meet different printing needs.

2. Flexible adjustment: The slitting machine has strong versatility and flexibility, which can be subdivided according to the specifications and types of different ribbons, and adjust and optimize the process parameters according to the quality of the finished film rolls.

3. Rewinding function: In addition to the slitting function, some thermal transfer ribbon slitters also have a rewinding function, which can rewind long ribbons into short rolls or convert cores of different specifications.

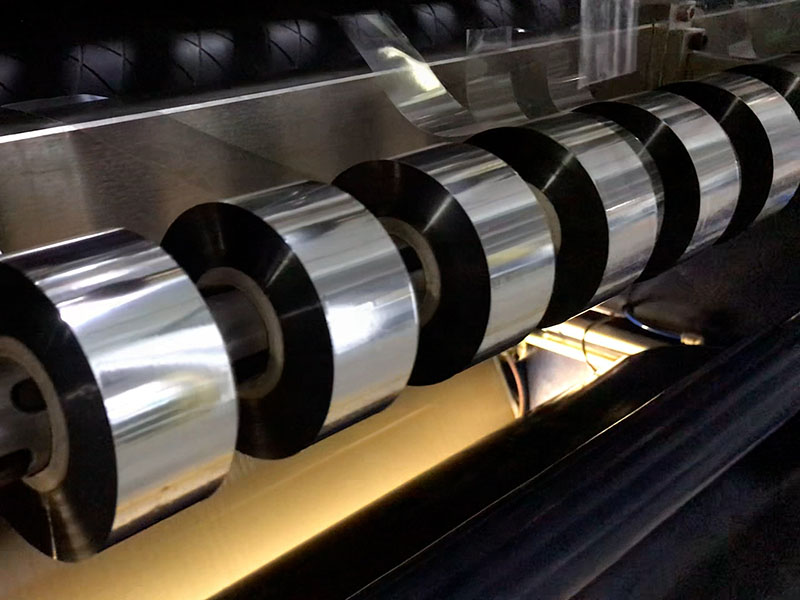

5. Stable and reliable mechanical structure

1. Sturdy and durable: The heat transfer ribbon slitting machine is usually welded with thick steel plates, with a firm structure and balanced angles, which can maintain smooth operation in high-speed working conditions.

2. High-precision parts: The whole machine adopts chrome-plated steel pipes and other high-precision parts, which are dynamically balanced to ensure the accuracy and stability of slitting.

6. Convenient operation and simple maintenance

1. Humanized design: The thermal transfer ribbon slitting machine usually adopts Chinese and English operation interface and LCD display, which is convenient for users to set parameters and monitor the status. At the same time, the device is also equipped with manual/automatic conversion function, which makes the operation easier and more convenient.

2. Easy maintenance: The design of the slitting machine usually takes into account the factors of easy maintenance, such as modular design, easy to disassemble parts, etc. This reduces maintenance costs and time, and increases the reliability and longevity of the equipment.

To sum up, the thermal transfer ribbon slitting machine plays an important role in the thermal transfer industry with its high-precision slitting ability, automation and intelligent control, tension control system, versatility and flexibility, stable and reliable mechanical structure, and convenient operation and simple maintenance.

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

This is not only an iteration of equipment, but also a comprehensive redefinition of production efficiency, material utilization and intelligent management standards.

27. February, 2026

It is in this context that the new generation of ribbon slitting machines is redefining the production standards of the industry with "precision manufacturing" as the core.

27. February, 2026