PVC slitting machine is mainly suitable for cutting PVC (polyvinyl chloride) materials and their related materials. The following is a detailed introduction to the applicable materials of PVC slitting machine:

1. PVC material

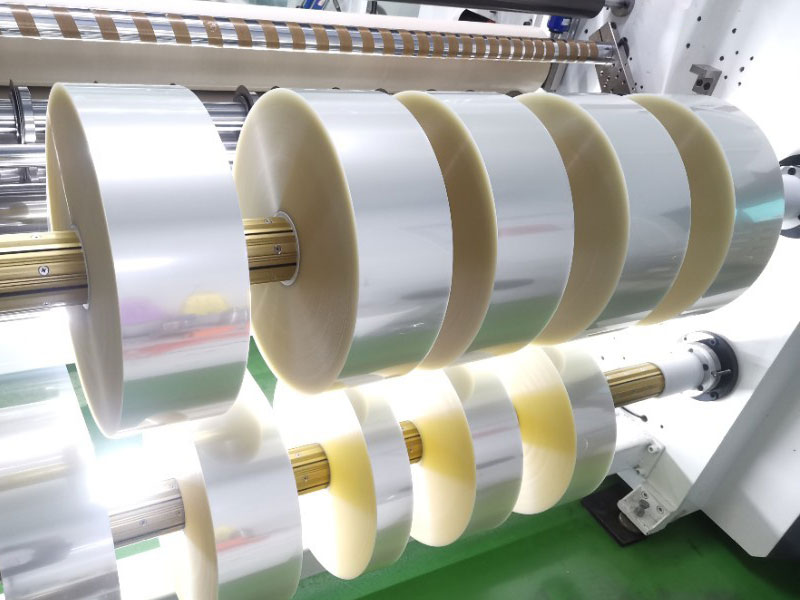

PVC, or polyvinyl chloride, is a thermoplastic resin that is polymerized from vinyl chloride under the action of an initiator. PVC slitting machine can efficiently and accurately cut PVC sheets, PVC films, etc., which have a wide range of applications in construction, advertising, printing, home improvement and other industries.

2. Related plastic materials

In addition to PVC material, PVC slitting machine is also suitable for other types of plastic materials, such as PE (polyethylene), PP (polypropylene), PET (polyethylene terephthalate), etc. These plastic materials are used in a wide range of applications in packaging, medical devices, construction and decoration, and PVC slitters are able to cut them precisely to meet the needs of various shapes and sizes.

3. Other thin materials

The PVC slitting machine is also suitable for the cutting of some thin materials, such as non-woven fabrics, leather, kraft paper, PE, PU, PT, EVA, etc. These materials have a wide range of applications in garment manufacturing, home textiles, industrial fabrics and other fields, and PVC slitting machines can cut them efficiently and improve production efficiency.

4. Materials in specific application scenarios

In some specific application scenarios, PVC slitting machine can also be used to cut some special materials, such as aluminum foil, paper, etc. These materials have certain application needs in packaging, construction, automotive and other industries, and PVC slitting machines can provide precise cutting services for them.

5. Precautions

Although PVC slitting machine has a wide range of applications, the following points should still be paid attention to during use:

1. Understand the material properties: When cutting different materials, you need to understand the characteristics of the material, such as hardness, toughness, thickness, etc., in order to choose the appropriate cutting parameters and tools.

2. Choose the right tool: Different materials need different tools for cutting, so when using a PVC slitting machine, you need to choose the right tool according to the characteristics of the material.

3. Adjust the cutting parameters: According to the characteristics of the material and the cutting requirements, adjust the cutting parameters of the PVC slitting machine, such as cutting speed, cutting depth, etc., to ensure the cutting quality and efficiency.

4. Pay attention to safety protection: When using the PVC slitting machine, you need to pay attention to safety protection, such as wearing protective glasses, gloves, etc., to avoid the splash and noise generated during the cutting process to cause injury to personnel.

To sum up, PVC slitting machine has a wide range of applications and is capable of cutting a variety of materials, including PVC materials, related plastic materials, thin materials, and materials in specific application scenarios. In the process of use, it is necessary to pay attention to the material characteristics, choose the right tool, adjust the cutting parameters and pay attention to safety protection.

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026

Among them, slitting effect, winding quality and tension control are the three core elements that determine the yield.

26. February, 2026

traditional slitting equipment has become difficult to meet the market's stringent needs for efficiency, precision, and flexibility.

26. February, 2026

choosing a professional PET film slitting machine is no longer a luxury option but a necessity to remain competitive.

06. February, 2026

It slits wide film into narrow rolls of various specific widths, and its technical level directly determines the quality and production efficiency of the end product.

06. February, 2026