The thermal transfer ribbon slitting machine is mainly suitable for the slitting of thermal transfer ribbon and other related ribbon materials. The following is a detailed summary of the materials it is suitable for:

First, the main applicable materials

1. Thermal Transfer Ribbon:

• Thermal transfer ribbon is an important consumable in thermal transfer printing technology, which is composed of three parts: base film, heat-resistant coating and ink coating. It can melt and transfer the ink to the substrate through the thermal transfer head to form text and images.

• The thermal transfer ribbon slitting machine can cut the thermal transfer ribbon and other materials into the required width according to the needs of the printed matter specifications.

2. Related ribbon materials:

• In addition to thermal transfer ribbons, thermal transfer ribbon slitting machines are also widely used in the slitting and rewinding of fax ribbons, strips, fax ribbons, tapes and other materials.

• These ribbon materials have strict requirements for slitting accuracy and width tolerance during the slitting process to ensure the quality of the final printed product.

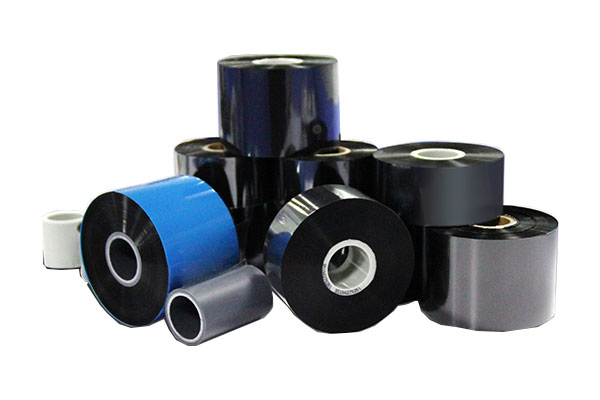

Second, the specific type of ribbon

1. WAX RIBBON:

• Usually contains a high percentage of wax-based feedstock that determines the melting point of the ribbon and thus affects the energy level required for printing.

• Due to the lower melting point of wax, the energy level required to print with wax-based ribbons is also relatively low. However, the durability of printed graphics is relatively poor.

2. WAX/RESIN RIBBON:

• Generally contains a high percentage of resin composition raw materials, which determines the high melting point of this ribbon.

• Hybrid-based ribbons require higher energy levels and produce better scratch and chemical resistance than wax-based ribbons.

3. RESIN RIBBON:

• Contains the highest percentage of resin composition and the highest energy level required for printing.

• Since the resin is harder than wax, the high resin content makes this ribbon extremely resistant to scuff and chemicals.

Third, other relevant materials

• In practical applications, the thermal transfer ribbon slitting machine may also be suitable for some special materials, such as metallized PET, POLYIMIDE and other high-strength, high-aesthetic synthetic materials. These materials place higher demands on thermal transfer ribbons, so they need to be printed with hybrid or resin-based ribbons.

To sum up, the thermal transfer ribbon slitting machine is suitable for the slitting of thermal transfer ribbon and other related ribbon materials, and has a wide range of application prospects and market demand. When choosing a thermal transfer ribbon slitting machine, you need to consider the requirements of the ribbon material, width, thickness and slitting accuracy to ensure that the slitting machine can meet the production needs.

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

This is not only an iteration of equipment, but also a comprehensive redefinition of production efficiency, material utilization and intelligent management standards.

27. February, 2026

It is in this context that the new generation of ribbon slitting machines is redefining the production standards of the industry with "precision manufacturing" as the core.

27. February, 2026