The technical parameters of the BOPP film slitting machine vary depending on the model, manufacturer and specific application scenario. Here are some common technical parameters of BOPP film slitting machine for your reference:

First, the basic technical parameters

1. Effective width: refers to the maximum film width that the equipment can handle. Common values are 500mm, 1300mm, etc., and there are also larger or smaller sizes, depending on the device model.

2. Mechanical speed: refers to the cutting speed of the equipment, usually in meters per minute (m/min). Common speeds range from 0-180m/min, but higher speeds may be achieved for high-end devices.

3. Maximum unwinding diameter: refers to the maximum diameter of the film roll that the equipment can unwind. Common values are 600mm, 800mm, etc., depending on the device model and configuration.

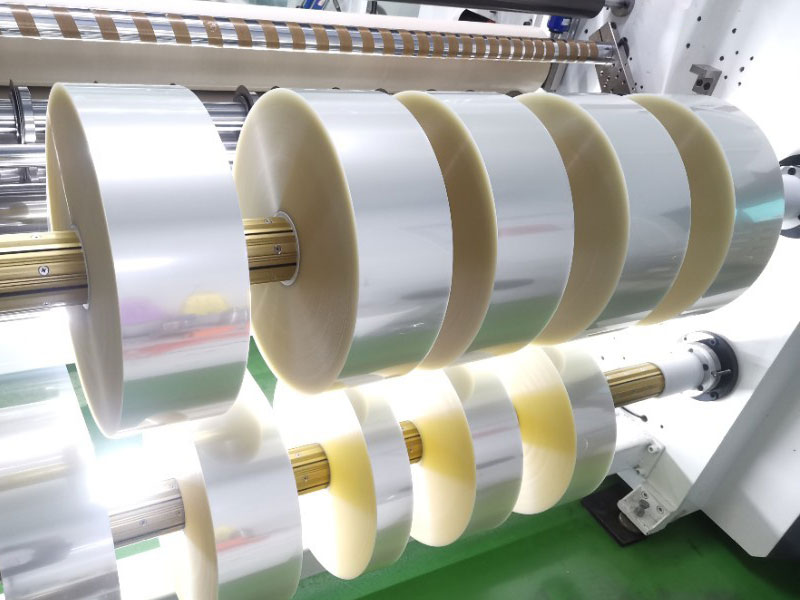

4. Maximum rewinding diameter: refers to the maximum diameter of the film reel that the equipment can rewind. Common values are 2-axis exchange 76.2-300mm, 450mm, etc., and there is also a larger size of the winding capacity.

5. Minimum slitting width: refers to the minimum width of the film that the equipment can cut. Common values are 12mm, 24mm, etc., depending on the configuration of the tool and equipment.

6. Diameter of paper core used in winding: refers to the diameter of the paper core or plastic core used in winding. Common values are 76mm (i.e., 76.2mm) or 3 inches (about 76.2mm).

Second, electrical and control system parameters

1. Motor power: refers to the power of the drive motor of the equipment, the common values are 3KW, 2.2KW, etc., depending on the equipment model and configuration.

2. Power supply: refers to the power supply voltage and frequency required by the device. Common values are three-phase 380V, 50Hz, and other voltage and frequency configurations are also available.

3. Control system: PLC (programmable logic controller) is usually used for automatic control to achieve stable operation and remote monitoring of equipment.

4. Counter: used to record the length of the film or the number of rolls cut, commonly known as a three-stage counter or a three-stage counter for frequency conversion speed regulation.

Third, other parameters

1. Unwinding tension control: Pneumatic brake control is usually used to ensure that the film maintains a stable tension during the unwinding process.

2. Rewinding tension control: Adopt double control, equipped with clutch and rewinding shaft independently, to ensure that the film maintains stable tension during the winding process.

3. Tool type: commonly used as industrial flat knife, suitable for film tape slitting. There are also equipment that uses other types of knives to meet different cutting needs.

4. Equipment size and weight: Depending on the equipment model and configuration, the external dimensions and weight of the equipment will also vary. Common equipment sizes vary from several meters in length, width and height, and weights range from a few hundred kilograms to several tons.

Please note that the above technical parameters are only common values, and not all BOPP film slitting machines have the same parameters. When selecting a device, select and configure it according to your specific needs and application scenarios.

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026

Among them, slitting effect, winding quality and tension control are the three core elements that determine the yield.

26. February, 2026

traditional slitting equipment has become difficult to meet the market's stringent needs for efficiency, precision, and flexibility.

26. February, 2026

choosing a professional PET film slitting machine is no longer a luxury option but a necessity to remain competitive.

06. February, 2026

It slits wide film into narrow rolls of various specific widths, and its technical level directly determines the quality and production efficiency of the end product.

06. February, 2026