Barcode ribbon slitting machine is an indispensable equipment in the label printing industry, mainly used to cut large rolls of ribbons into small rolls suitable for different printing needs. With the rapid development of the label printing industry, the application of barcode ribbon slitting machine is becoming more and more extensive, and it has become an important tool to improve production efficiency and ensure product quality.

1. The role of barcode ribbon slitting machine

• Precise slitting: Slitting large ribbons into the required width to meet the needs of different printers.

• Improve efficiency: automatic slitting reduces manual operation and improves production efficiency.

• Cost Reduction: Reduce material waste and reduce production costs.

2. Application in label printing industry

• Barcode label printing: The slitted ribbon is used in the barcode printer to ensure that the barcode is clear and readable.

• Logistics label printing: The logistics industry needs a large number of labels, and the slitting machine ensures the supply of ribbons.

• Retail Label Printing: The retail industry uses slitting ribbons to print price tags and product information.

• Pharmaceutical label printing: The pharmaceutical industry has high requirements for labels, and the slitting machine ensures the quality of the ribbon.

3. Advantages of barcode ribbon slitting machine

• High precision: Ensure consistent slitting width to avoid printing problems.

• Automation: Reduce manual intervention and increase productivity.

• Versatility: Suitable for multiple types of ribbons to meet different needs.

• Energy saving and environmental protection: reduce material waste and reduce environmental impact.

4. Practical application cases

After a label printing company introduced a barcode ribbon slitting machine, the production efficiency was increased by 30%, the material waste was reduced by 15%, the product quality was significantly improved, and the customer satisfaction was greatly improved.

5. Future development trends

• Intelligent: Combine the Internet of Things and artificial intelligence to achieve intelligent monitoring and optimization.

• High speed: Increase the slitting speed to meet the needs of mass production.

• Eco-friendly: Adopt eco-friendly materials and energy-saving technologies to reduce carbon footprint.

conclusion

Barcode ribbon slitting machines play an important role in the label printing industry, helping companies improve their competitiveness by precise slitting, improving efficiency and reducing costs. With the advancement of technology, the slitting machine will be more intelligent, high-speed and environmentally friendly, and promote the sustainable development of the label printing industry.

This article will comprehensively analyze the functional system of ribbon slitting machine and reveal how it achieves precise control from raw materials to finished products.

10. February, 2026

a machine that completes the three functions of slitting, rewinding and detection at the same time, and ribbon production ushers in an era of integrated intelligence.

10. February, 2026

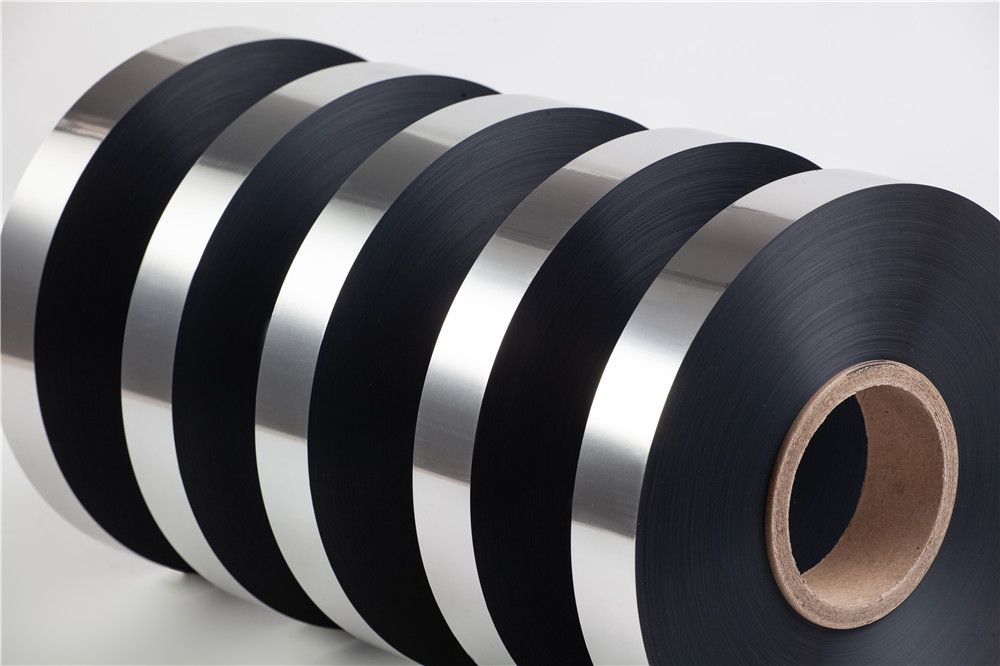

From the large coil of raw material to the finished small coil in the hands of the end user, ribbon needs to go through a precise slitting process, which is the mission of ribbon slitting machines.

10. February, 2026

The core of the high-precision ribbon slitting machine lies in the precise mechanical structure design.

07. February, 2026

and the synergy between the two determines the quality of ribbon slitting and is the core code for interpreting modern ribbon slitting technology.

07. February, 2026