The growth of the market demand for barcode ribbon slitting machines is closely related to the increasing demand for barcode labeling and printing in several industries. Here's a look at what's next:

1. Automation and intelligence

With Industry 4. 0 and the advancement of intelligent manufacturing, barcode ribbon slitting machine will increasingly integrate automation and intelligent technology. The equipment of the future will have a higher level of automation, capable of automatic loading, cutting, inspection and packaging, reducing manual intervention and improving production efficiency and accuracy.

2. High precision and high efficiency

The market is demanding more and more precision from barcode labels, especially in industries such as medical, electronics, and retail. The slitter of the future will use more advanced sensors and control systems to achieve high-precision cutting at the micron level, while increasing the cutting speed to meet the needs of high-volume production.

3. Versatility and flexibility

Different industries have different requirements for the specifications and materials of barcode ribbons. The slitter machine of the future will be more versatile and flexible, able to adapt to the cutting needs of a variety of materials and specifications, and enhance the market adaptability of the equipment.

4. Environmental protection and energy saving

With the increasingly strict environmental protection regulations and the popularization of the concept of sustainable development, the future slitting machine will pay more attention to energy conservation and environmental protection. The equipment will adopt more efficient energy utilization technology and environmentally friendly materials to reduce waste generation and energy consumption, and meet the requirements of green manufacturing.

5. Customization and personalization

There is an increasing demand for customized and personalized barcode labels. In the future, the slitting machine will have stronger customization capabilities, and can be personalized and produced according to the specific needs of customers to meet the diversified market demand.

6. Internet of Things and remote monitoring

The application of IoT technology will enable the slitter machine to have remote monitoring and diagnosis functions. Through IoT Platform, users can monitor the running status of devices in real time, perform remote fault diagnosis and maintenance, and improve the operation efficiency and reliability of devices.

7. Market expansion and application field broadening

With the wide application of barcode technology in logistics, retail, medical, manufacturing and other fields, the market demand for barcode ribbon slitting machine will continue to grow. The expansion of emerging markets and application areas will bring new growth opportunities for slitters.

summary

The growth of the market demand for barcode ribbon slitting machine will promote the development of equipment in the direction of automation, intelligence, high precision, high efficiency, environmental protection and energy saving and customization. The application and market expansion of IoT technology will further promote the rapid development of the industry. In the future, barcode ribbon slitting machine will play a more important role in many industries to meet the growing market demand.

This article will comprehensively analyze the functional system of ribbon slitting machine and reveal how it achieves precise control from raw materials to finished products.

10. February, 2026

a machine that completes the three functions of slitting, rewinding and detection at the same time, and ribbon production ushers in an era of integrated intelligence.

10. February, 2026

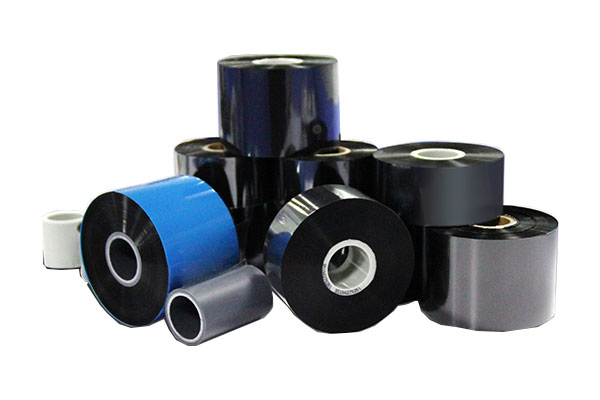

From the large coil of raw material to the finished small coil in the hands of the end user, ribbon needs to go through a precise slitting process, which is the mission of ribbon slitting machines.

10. February, 2026

The core of the high-precision ribbon slitting machine lies in the precise mechanical structure design.

07. February, 2026

and the synergy between the two determines the quality of ribbon slitting and is the core code for interpreting modern ribbon slitting technology.

07. February, 2026