Overview of industry applications

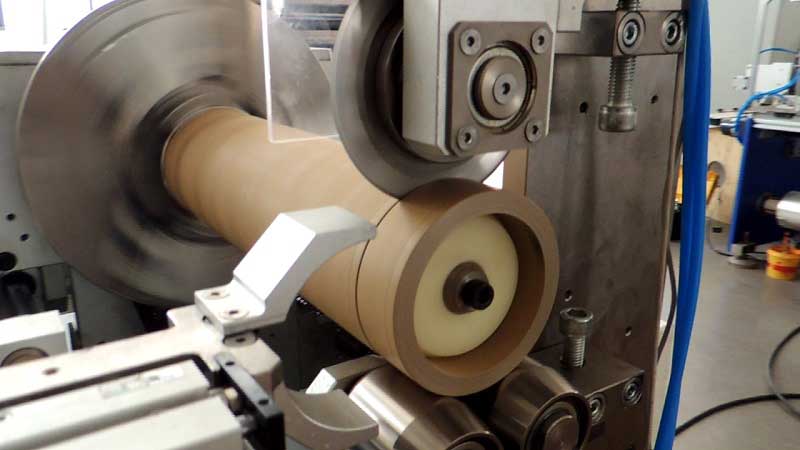

Paper tube cutters play an important role in various industries, and different industries have unique needs for paper core cutting:

• Textile industry: Paper tubes that require high-precision cutting are used for yarn winding

• Packaging industry: Paper tubes of different diameters and lengths are required for product packaging

• Paper industry: Large-scale production requires efficient and durable cutting equipment

• Construction industry: Special composite paper tubes require special cutting processes

Customized solutions

1. Size customization

• Adjustable cutting length range (50mm-3000mm)

• Multiple diameters (Φ10mm-Φ500mm)

• Special bevel angle (30°-60°) to meet specific packaging needs

2. Material adaptability

• Adjust the cutting parameters for different thicknesses (0.5mm-15mm).

• Special cutting blade for specially coated paper cores

• Dedicated solutions for composite paper tubes (e.g. aluminum foil lamination).

3. Degree of automation

• From manual operation to fully automated line integration

• Intelligent recognition system automatically adjusts cutting parameters

• Seamless integration with existing production lines

Technological advantages

1. High-precision cutting: ± 0.1mm tolerance control

2. Efficient production: up to 120 cuts/min at the earliest

3. Energy saving and environmental protection: low energy consumption design, reduce waste generation

4. Safe and reliable: multiple safety protection devices

5. Intelligent control: touch screen operation, parameter memory function

After-sales service guarantee

• Professional engineer team to provide on-site installation and commissioning

• 24-hour technical response

• Regular maintenance schedules

• Rapid replacement of wearing parts

• Operator training courses

Customized paper tube cutting machine can provide personalized solutions according to the specific needs of customers, helping various industries to improve production efficiency, reduce production costs, and improve product quality.

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025