The multi-specification adaptation and flexible cutting function of the paper tube cutter are the key technologies in modern paper tube processing, which can meet the diverse needs of different industries for paper core size, accuracy and efficiency. Here's a closer look at the feature:

Core features:

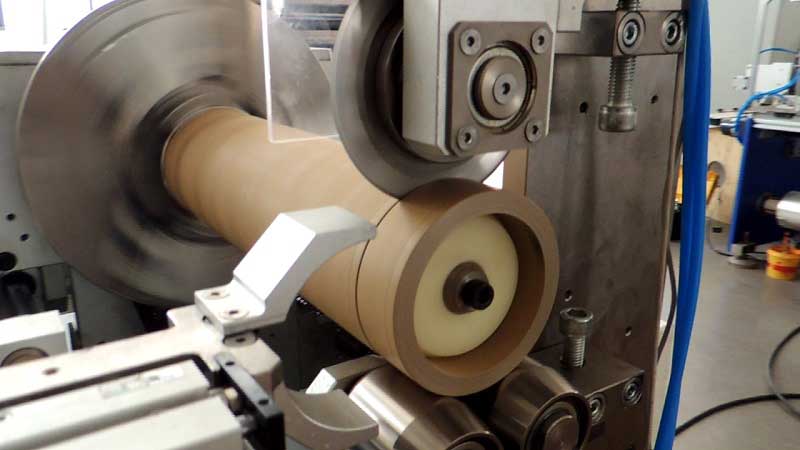

1. Automatically adjust the cutting length

◦ The digital control system can preset a variety of cutting specifications

◦ The minimum cutting length can be up to 10 mm, and the maximum cutting length can be up to 6 meters

◦ The accuracy error is controlled within ±0.2mm

2. Multi-diameter adaptability

◦ With the interchangeable fixture system, paper cores with a diameter of 20 mm to 500 mm can be processed

◦ The automatic centering device ensures the cutting accuracy of paper cores of different diameters

3. Angle cutting function

◦ The cutting angle can be adjusted from 0-45°

◦ Bevel mode for special fitting needs

How the technology is implemented

1. Intelligent control system

◦ PLC+touch screen operation interface

◦ Hundreds of cutting solutions can be stored

◦ Support barcode scanning to automatically recall cutting parameters

2. Mechanical adjustment mechanism

◦ High-precision feed system driven by servo motor

◦ Pneumatic/hydraulic clamping device

◦ Quick-change tool design

3. Detection and feedback system

◦ The laser rangefinder monitors the paper core length in real time

◦ Pressure sensor ensures proper cutting force

◦ Automatic web correction function

Industry application advantages

1. Packaging industry

◦ Adapt to different specifications of carton packaging

◦ Quickly switch between different packaging needs such as cosmetics and food

2. Textile industry

◦ Precise cutting of all kinds of cloth core tubes

◦ The bevel cutting function meets the requirements of special textile processes

3. Construction industry

◦ Custom cutting of paper tubes for high-strength concrete formwork

◦ Rapid changeover of specifications for mass production

Operational precautions

1. Equipment calibration must be performed before changing specifications

2. Different diameters of paper cores need to use corresponding support fixtures

3. Check tool wear regularly

4. Keep the rails and drive system clean and lubricated

This multi-format tube cutter significantly increases production flexibility, reduces equipment investment and changeover time, and is ideal for modern tube processing.

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025