In the paper core (core, tube) processing industry, efficient and precise cutting equipment is essential. With its compact design, intelligent operation and stable performance, the paper tube cutter has become a powerful tool to improve production efficiency. Whether it's packaging, textile, printing or industrial paper tubes, choosing the right tube cutter can make production easier and more efficient.

1. The core advantages of the paper tube cutter

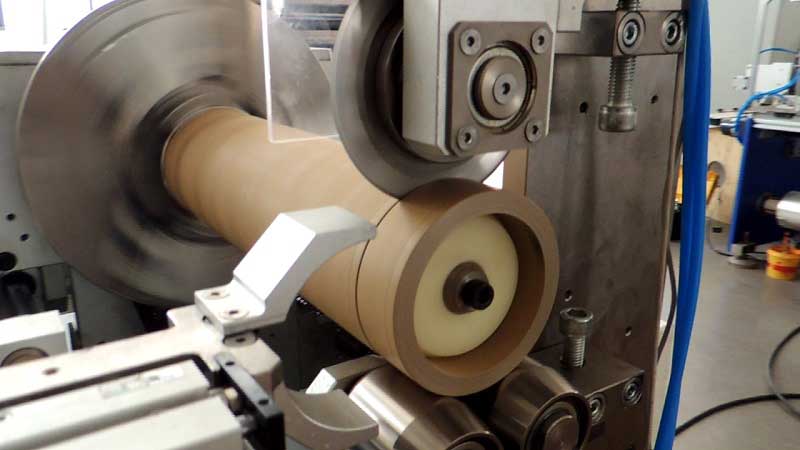

✅ High-precision cutting - to ensure that the incision is smooth and burr-free, and the tolerance can be controlled within ±0.1mm, reducing the subsequent grinding process.

✅ Efficient production - automatic feeding, automatic cutting, the speed can reach 100-300 knives/min, 5-10 times faster than manual cutting.

✅ Flexible adaptation - can cut different materials (kraft paper, white cardboard, composite) and different diameters (10mm-500mm) paper cores.

✅ Labor saving - high degree of automation, 1 person can operate multiple equipment, reducing labor costs.

✅ Safe and stable - equipped with protective cover and emergency stop device to reduce the risk of work-related injuries.

2. How to choose the right paper tube cutter?

(1) Select according to the cutting method

| type | Applicable scenarios | advantage | limitations |

| Round knife cutting | Thin wall paper tube (<5mm) | The speed is fast and the incision is smooth | Not suitable for thick-walled tubing |

| Serrated knife cutting | Thick wallpaper tube (>5mm) | The cutting force is strong and not easy to deform | The incision is slightly rougher |

| Laser cutting | High-precision special-shaped cutting | No contact cutting, no burrs | High cost of equipment |

(2) Select according to the degree of automation

• Manual paper tube cutter: suitable for small batch production, low price, but low efficiency.

• Semi-automatic paper tube cutting machine: manual feeding, automatic cutting, cost-effective.

• Automatic paper tube cutting machine: automatic feeding, cutting, stacking, suitable for large batch continuous production.

(3) Key parameter considerations

• Cutting length range: such as 50mm-2000mm, is it adjustable?

• Cutting accuracy: ±0.1mm (high precision) or ±1mm (normal)?

• Applicable pipe diameter: minimum and maximum diameter (e.g. 20mm-300mm)?

• Motor power: Determines the cutting capacity (e.g. 1.5kW-5kW).

3. Examples of application industries

📌 Packaging industry – paper cans, cosmetic tubes, tea cans, etc

📌 Textile industry – bobbins, cloth cores

📌 Printing industry - web core, tape tube

📌 Industrial field - film core, industrial paper tube

4. Purchase advice

🔹 Test Cutting Sample: Provide the actual paper core to test the cutting effect.

🔹 Inspect the brand: give preference to manufacturers with industry experience.

🔹 After-sales service: to ensure technical support, spare parts supply in a timely manner.

summary

Although the paper tube cutter is "small", it can greatly improve production efficiency and reduce costs. Choose the right model according to your own needs (material, output, precision) to make paper core processing smarter and easier!

If you need specific model recommendation or technical consultation, welcome to further communication!

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025