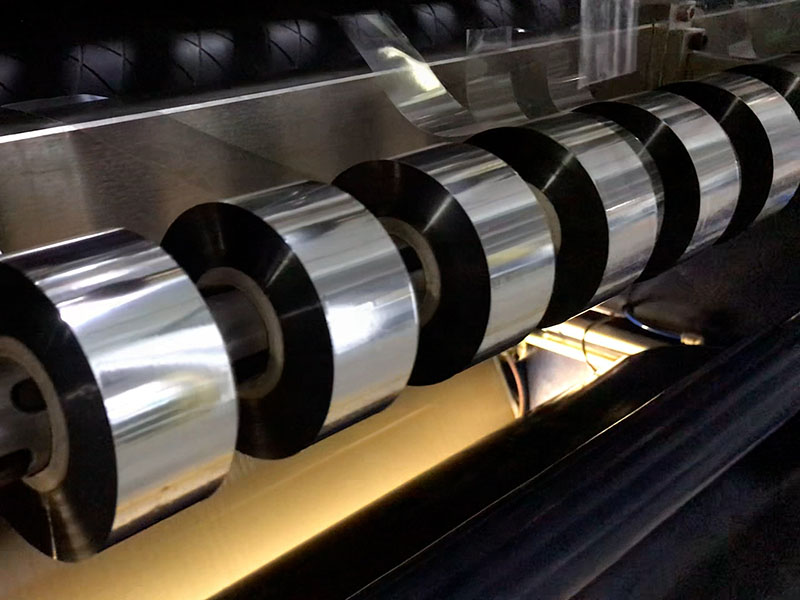

As the core equipment of the label printing industry, the ribbon slitting machine has much more than a simple "cutting". The following is a comprehensive analysis of its "magic" from the core technology to the application scenario, and take you to understand how this equipment has become the invisible hero of modern industry:

First, "surgical scalpel" in the field of precision manufacturing

1. Nano-scale guiding system

Using a high-sensitivity photoelectric sensor + AI algorithm, the edge position of the ribbon is monitored in real time, and even the offset of 0.1mm can be automatically corrected (far exceeding the ±0.5mm standard of manual operation) to ensure that the slitting line is as accurate as a surgical incision.

2. Dynamic tension control

Equipped with magnetic particle brake and PID closed-loop control system, it keeps the tension constant (error <2%) in the start-stop and acceleration phases, avoiding the "serpentine roll" phenomenon common to traditional equipment, especially suitable for ultra-thin ribbons (such as 1.5μm thickness).

Second, intelligent "industrial brain"

1. Visual quality inspection integration

The built-in industrial camera can automatically identify pinholes, bubbles, impurities and other defects on the surface of the ribbon (with an identification accuracy of 10μm), and automatically mark the defect position by the laser marking machine to achieve quality traceability.

2. Digital twin pre-tuner

By inputting the ribbon material (polyester/polyimide), width and other parameters, the system automatically simulates the slitting process and recommends the best knife pressure, speed and other parameters, reducing the test loss by 30%.

Third, the "Transformers" ability for special scenes

1. Ultra-narrow web slitting technology

The vacuum adsorption winding device can realize the slitting of 2mm width ribbon (equivalent to the thickness of a toothpick) to meet the needs of micro electronic component labels.

2. Anti-static treatment module

Integrated ionic air bar and grounding system, the surface resistance is controlled in the range of 10^6-10^8Ω to prevent electrostatic adsorption of dust during slitting and affect the life of the print head.

Fourth, the "energy-saving expert" of green production

• Waste edge recycling system: automatically separates waste scrap materials and collects them through negative pressure pipelines, with a recovery rate of > 99%, reducing material waste by 15% compared with traditional methods.

• Inverter energy-saving mode: standby power consumption < 0.5kW, 40% less energy than older equipment.

Industry application breakthrough cases

• Medical label field: When cutting medical-grade ribbons, aseptic packaging is completed in a 10,000-level clean environment, which meets the requirements of GMP certification.

• Aerospace field: slitting high-temperature resistant ribbon (-70°C~300°C) is used for aircraft cable identification, and the slitting accuracy is ±0.01mm.

After understanding these functions, have you noticed that the ribbon slitting machine in the workshop is actually a precision work of art that combines mechanical engineering, materials science and automatic control technology?

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

This is not only an iteration of equipment, but also a comprehensive redefinition of production efficiency, material utilization and intelligent management standards.

27. February, 2026

It is in this context that the new generation of ribbon slitting machines is redefining the production standards of the industry with "precision manufacturing" as the core.

27. February, 2026