The demand for customization in the automotive film industry is growing, and the upgrade of the solar film slitting machine, as a key equipment, is crucial to solving the customization problem. Here are the solutions:

Core technology upgrade

1. Intelligent CNC system

◦ Controlled by high-precision servo motor, it achieves a cutting accuracy of ±0.1mm

◦ Integrated direct import of CAD drawings simplifies the customization process

◦ Equipped with a touch screen human-machine interface, parameter setting is intuitive and simple

2. Adaptive cutting technology

◦ The laser sensor monitors the position of the film in real time and automatically adjusts the cutting path

◦ The pressure sensing device automatically adjusts the cutting force according to the thickness of the film

◦ Edge recognition system ensures precision in profiled cutting

Customized functions are implemented

1. Flexible size adjustment

◦ Infinitely adjustable cutting width to adapt to various vehicle vehicle sizes

◦ Quick tooling system to meet special shape requirements

◦ Memory storage function to save frequently used model parameter configurations

2. Multi-material compatibility

◦ Adjustable blade system to accommodate different thicknesses of solar film

◦ Temperature control system to prevent thermal deformation during high thermal insulation film cutting

◦ Anti-static device to ensure that the thin film material is cut flat

Efficiency improvement plan

1. Automation integration

◦ Automatic loading/winding system to reduce manual intervention

◦ Online quality inspection, real-time elimination of unqualified products

◦ Interface with ERP/MES system to achieve intelligent production scheduling

2. Quick switching system

◦ Modular design, complete product changeover within 15 minutes

◦ One-click parameter calling reduces debugging time

◦ Automatic tool sharpening system to extend the continuous working time of the equipment

Industry value creation

With these upgrades, the solar film slitting machine is able to:

• Reduced lead times for customized products by more than 40%

• Material utilization rate increased to more than 95%

• 30% reduction in low-volume custom production costs

• Meet the film needs of special shape glass for new energy vehicles

These technological innovations will effectively solve the customization problems faced by the automotive film industry and promote the transformation of the industry to flexible and intelligent production.

This article will delve into how advanced automotive film slitting machines can help businesses achieve their goal of doubling production capacity.

04. February, 2026

These film materials need to be precisely cut into different widths during the production process to meet the needs of various models and components.

10. December, 2025

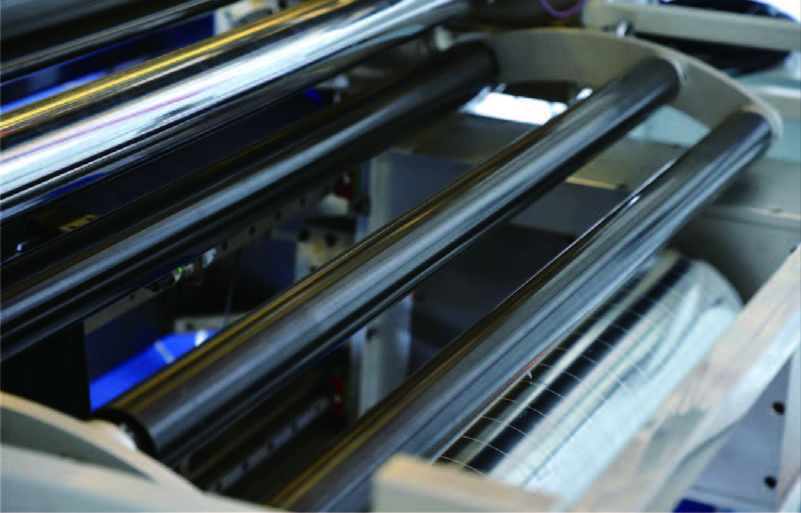

The automotive film slitting machine, an increasingly intelligent "cutting knife", is accurately cutting out redundant costs, inefficient processes and backward production methods.

10. December, 2025

It cuts wide raw film rolls into various sizes required by customers with millimeter-level accuracy.

02. December, 2025

What it completes is not only a physical form cutting, but also a profound value sublimation.

02. December, 2025