In today's era driven by green energy and sustainable transportation, lithium batteries, as a core power source, are changing our world at an unprecedented rate. From new energy vehicles shuttling through city streets to energy storage power stations storing clean energy, behind every high-performance lithium battery, a set of precise, efficient and crucial manufacturing equipment is inseparable. Among them, the lithium battery slitting machine, an unknown "tailor master" in the middle of manufacturing, is empowering strong power with its exquisite skills in millimeters and cutting a precise path for the future of the industry.

1. Dispute over the slightest: the "lifeline" of the power battery is cut

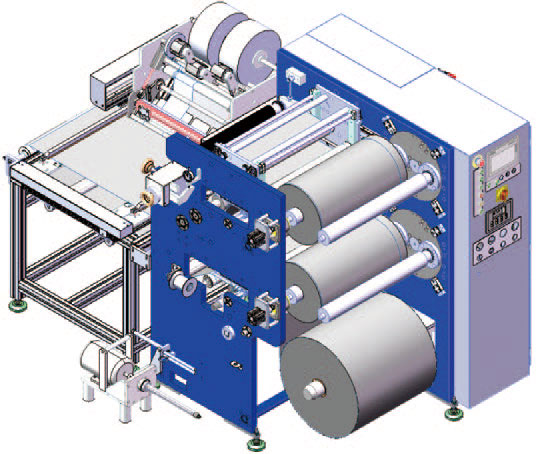

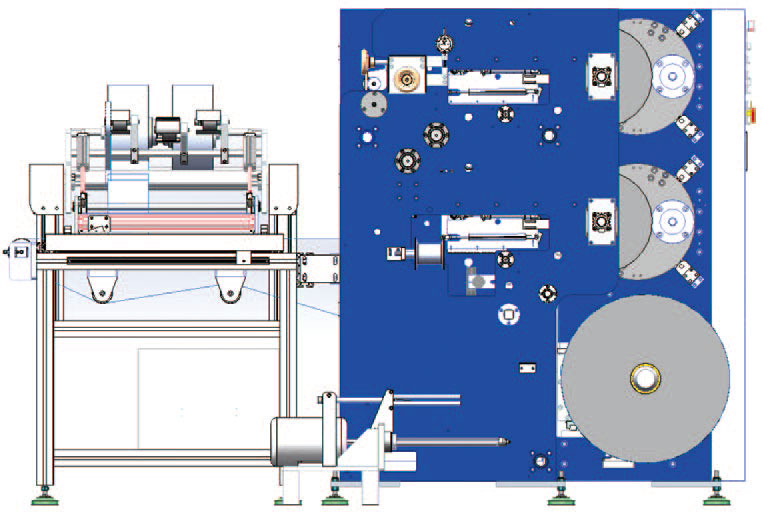

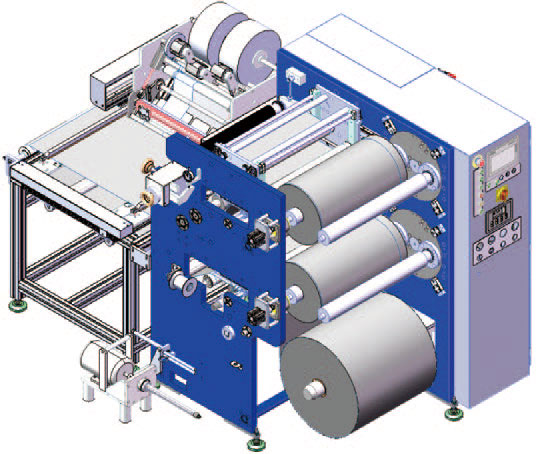

The manufacturing of lithium batteries is a microscopic competition that requires the utmost precision and cleanliness. After the coating process, a wide ribbon pole piece is obtained. The mission of the slitting machine is to cut this wide pole piece into multiple narrow strips with consistent width, neat edges, and no burrs according to the design requirements of the battery cell.

This is by no means a simple "cropping". The process of slitting is the key to determining the internal resistance, consistency, safety and energy density of the battery. Even a micron-level size deviation, a trace of burrs or metal dust that is imperceptible to the naked eye can become a "short circuit point" inside the battery, which can affect battery life at best, cause thermal runaway at worst, and bury potential safety hazards. Therefore, the work of the slitting machine is to cut out its efficient and safe "lifeline" for each power battery. It replaces the traditional "scissors" with extremely sharp cutting edges, and uses a circular knife that rotates at high speed to accurately cut or tear to ensure that each pole piece is carved out of a mold, laying the perfect foundation for the subsequent winding or lamination process.

2. Empowering power: the technological leap behind precision manufacturing

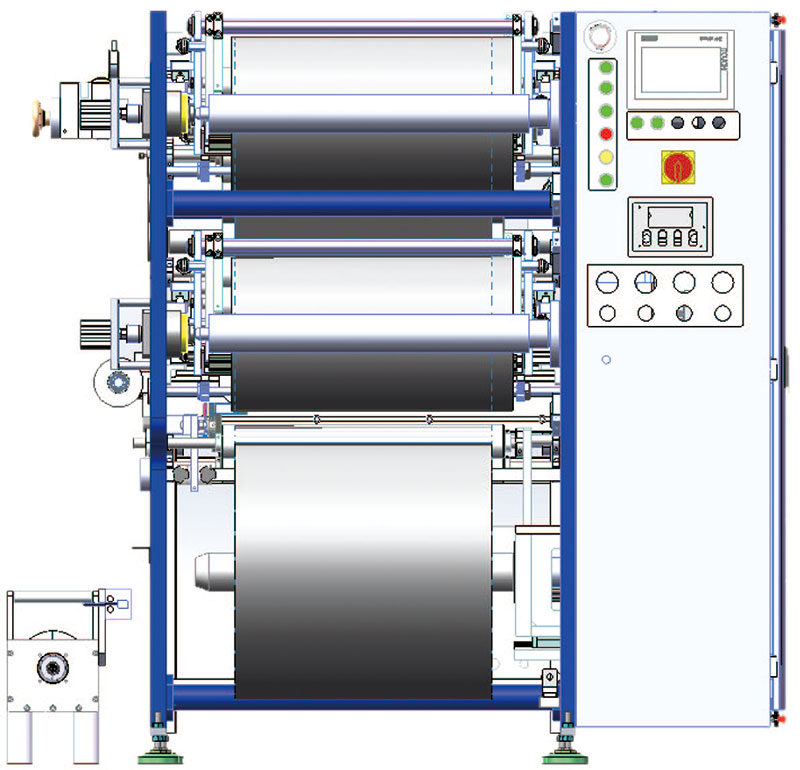

"Empowering power" not only refers to the lithium battery providing energy for vehicles and equipment, but also refers to the technological progress of the slitting machine itself to inject a strong driving force into the entire lithium battery industry. Modern high-end slitting machines are no longer a simple machine.

• Intelligent "brain": Integrating advanced motion control systems and machine vision systems, it can monitor tension, correct deviations, and detect defects in real time, achieving fully automatic and uninterrupted high-precision production.

• Extremely stable "body": The use of highly rigid body structure and precise transmission components effectively suppresses vibration, ensuring that the slitting speed of up to 100 meters per minute is still rock-solid, ensuring the stability of quality.

• Clean and environmentally friendly "core": The built-in efficient dust removal system can suck away metal dust at the moment of slitting, maintain the cleanliness of the production environment, and improve the safety and quality of the battery from the source.

It is the culmination of these technologies that enables the slitting machine to meet the manufacturing requirements of a new generation of high-energy density and large-size battery poles, and truly "empowers" the surging performance of power batteries.

3. Cutting the future: a blueprint for more efficient and intelligent manufacturing

"Cutting out the future" depicts an imaginative industrial picture. With the global pursuit of carbon neutrality goals, the demand for lithium batteries has grown explosively, putting forward higher requirements for manufacturing efficiency, cost and intelligence. Slitting machines, as a key link connecting the upper and lower links, are moving towards a broader future.

• Cutting "efficiency": By increasing the slitting speed, reducing the frequency of tool changes, and achieving non-stop docking, the overall equipment efficiency (OEE) is maximized to meet the needs of large-scale production capacity.

• Cutting out "data": The integration of industrial Internet and digital twin technology makes slitting machines become data nodes in smart factories. The slitting data of each roll of pole pieces is recorded and analyzed for process optimization, predictive maintenance, and transparency and intelligence in the manufacturing process.

• Adaptability of cutting "new materials": In the face of the emergence of new system battery materials such as silicon-carbon anodes and solid-state batteries, slitting machines need to continuously innovate to meet the challenges of different physical properties brought by new materials and always maintain the leading edge of the process.

epilogue

Lithium battery slitting machine, although hidden in a huge production line, is not famous, but its achievements are great. It is a practitioner of building a macro-green future at the micro scale. Every inch of the pole piece that is accurately cut is a modern interpretation of the "craftsman spirit"; Every iterative upgrade of technology is laying a high-speed track to the future for the power battery industry.

As the saying goes: "In a millimeter, empower strong power; With precision blades, cut out the infinite future. This silent "master tailor" is driving us to accelerate towards a cleaner and smarter electrified tomorrow with its indispensable role.

Equipment for high-speed, high-precision slitting of wide metal strips (such as aluminum strips, nickel strips, or copper-aluminum composite strips) into the required width and number of tabs.

27. October, 2025

This is achieved through a system engineering that combines mechanical engineering, materials science, automatic control and sensing technology.

12. September, 2025

The technical level of the slitting machine directly determines the yield, quality consistency of the separator, and the safety and performance of the final battery.

27. August, 2025

Below I will elaborate on how to improve cutting quality through parameter optimization from three aspects: core parameters, optimization strategies, and systematic methods.

22. August, 2025

The following are the application and technical points of film slitting machine in lithium battery separator slitting process:

04. July, 2025