As we all know, we often have a lot of industrial dust on the machine after operating the slitting equipment, these are "toxic and harmful gases", easy to suffer from occupational diseases for a long time, very bad for the lungs, then, what equipment can effectively solve these problems?

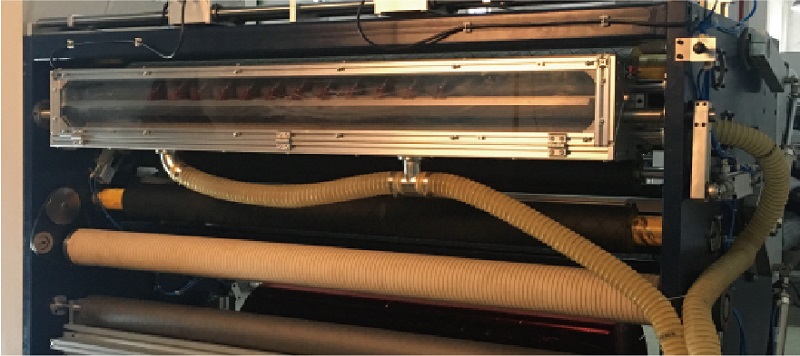

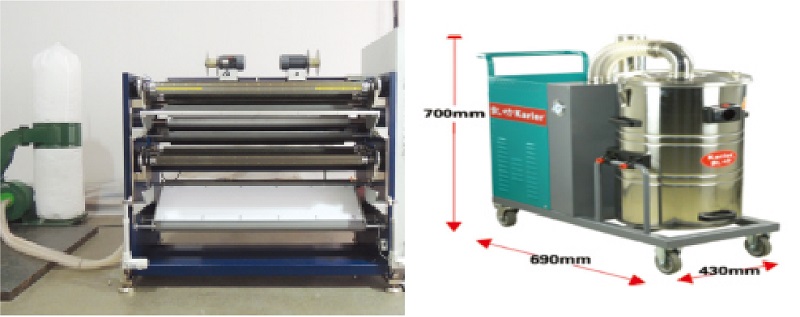

In view of this problem, the slitting machine manufacturer has researched and produced a dust treatment device, which effectively solves the dust generated after suctioning and slitting.

Operation method: wipe through felt (white mineral oil can be added) and dust removal hood vacuuming; Material: tungsten steel blade, surface treatment: grinding, polishing, full throwing; And the angle can be customized, and the bedknife can be customized according to different specifications according to customer requirements.

The scope of application is commonly found in soft materials such as paper, packaging film, and non-woven fabrics.

If you are still troubled by the dust removal of the slitting machine, you may wish to consult us in detail through the network or telephone, or you can come to our factory to meet and negotiate.

Slitting, this seemingly simple action, is actually the ultimate pursuit of precision.

03. March, 2026

They will be shipped to cigarette packaging factories, wine box factories, gift wrapping companies, and finally become those memorable and beautiful packaging in our hands.

03. March, 2026

Every micron-level improvement in slitting accuracy, every percentage decrease in scrap rate, is a scale of industry progress.

03. March, 2026

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026