Slitting machine is a kind of equipment used to automatically cut large coils of materials into small rolls or other sizes, which is widely used in industrial production. This article will introduce the working principle of the slitting machine, the application scenarios, and how to improve its production efficiency.

First, the working principle of the slitting machine

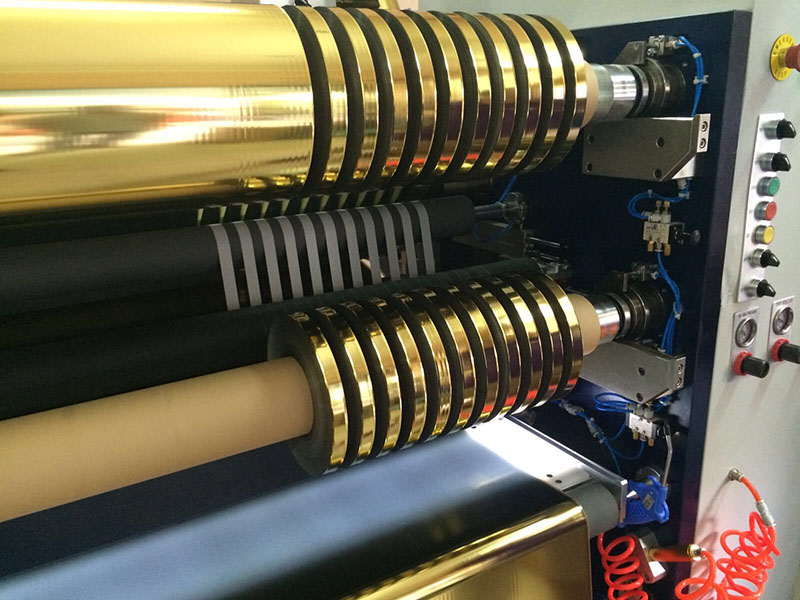

The slitting machine is mainly composed of feeding system, slitting system, unwinding system, tensioning control system and hydraulic control system. Its working principle is to place the large coil of material on the unwinder, automatically feed the material into the slitter through the feeding system for automatic slitting, and then the small coil material after completion is centrally stored through the winding device.

Second, the application scenario of the slitting machine

Slitting machines are widely used in plastic products, textiles, electronic products and other industries, suitable for slitting processing of various materials. Different industries have different requirements for material size and color, and slitting machines can meet these needs.

Third, how to improve efficiency?

Optimize hydraulic and pneumatic systems: The slitting machine mainly drives its operation through pneumatic and hydraulic control systems, and optimizing these systems can improve the operational efficiency and production quality of the slitting machine.

Introduction of intelligent control system: The slitting machine can improve production efficiency by introducing intelligent control system (such as PLC control system, etc.) to carry out intelligent scheduling of production planning and automatic adjustment of coil size.

Cycle maintenance: The slitting machine needs regular maintenance, such as cleaning, maintenance, replacement and sharpening, etc., so as to extend the life of the equipment and improve production efficiency.

Conclusion:

Slitting machine is an indispensable equipment in modern industrial production, which can automatically and quickly cut large coils of materials into small rolls or other sizes of materials, which are widely used in all walks of life. We can improve the production efficiency of the slitting machine by optimizing the hydraulic and pneumatic system, introducing intelligent control system, carrying out regular maintenance, etc., further optimize the entire production process, and improve production efficiency and quality.

Slitting, this seemingly simple action, is actually the ultimate pursuit of precision.

03. March, 2026

They will be shipped to cigarette packaging factories, wine box factories, gift wrapping companies, and finally become those memorable and beautiful packaging in our hands.

03. March, 2026

Every micron-level improvement in slitting accuracy, every percentage decrease in scrap rate, is a scale of industry progress.

03. March, 2026

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026