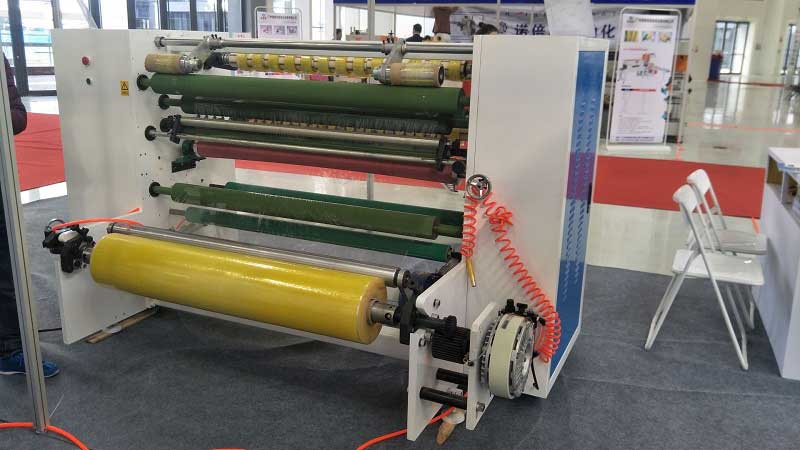

Tape slitting machine is a tape processing tool used to cut the tape according to a certain size, using which we can cut the tape according to any adjustment scale. So do you know what are the differences between the tape slitting machine before feeding and post-feeding?

First,Pre-discharge type OPP slitting machine: the mother coil is placed from the operation direction (that is, the winding direction) and is called the front discharge type.

1. Braking mode: mechanical manual brake.

2. Noise reduction mode: manual pulling of the plate.

3. The two main drive shafts are used for film pulling transmission, and the anti-wrinkle treatment is done without flattening rods.

Second, the post-discharge type OPP slitting machine: the mother coil is placed from the back of the operation direction (that is, the winding direction) and is called the post-discharge type.

1. Braking mode: adjustable pneumatic brake (optional electromagnetic brake).

2. Noise reduction mode: automatic air pressure wheel.

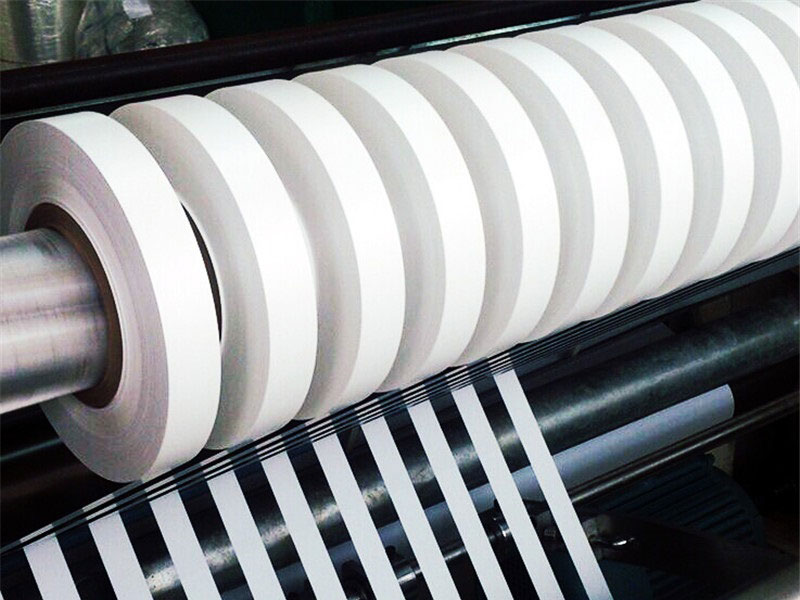

3. The two main drive shafts are used for film pulling transmission, and there are flattening rods for anti-wrinkle treatment.

4. Winding is a slip differential shaft for double tension control tape slitting machine.

at the heart of the process of transforming huge master rolls into a dazzling array of small finished rolls, the tape slitting machine

18. October, 2025

it needs to be controlled from various aspects such as equipment adjustment, material selection, process parameter optimization, and operation specifications.

14. August, 2025

The following are the core advantages of single-sided adhesive slitting machines and their role in enhancing tape production:

12. August, 2025

Systematic optimization is carried out from multiple dimensions such as mechanical structure, control system, material science and human-computer interaction.

07. June, 2025

It improves production efficiency and is ideal for modern slitting production.

27. April, 2025