Slitting machine is a kind of mechanical equipment that cuts wide paper or film into a variety of narrow materials, commonly used in paper machinery and printing and packaging machinery, the traditional control scheme of the slitting machine is to use a large electric motor to drive the rewinding and unwinding shafts. Magnetic particle clutches are added to reels and reels, as well as drag control created by magnetic clutches to control the tension on the surface of the material. Magnetic particle clutches and brakes are special automatic actuators that transmit torque through magnetic particles filled in the working gap. The magnetic current can be changed to change the magnetic state of the magnetic particle, and then the transmitted torque can be adjusted. It can be used for stepless speed regulation from zero to synchronous speed. It is suitable for high-speed partial fine-tuning and small and medium-power speed regulation systems. It is also used in unwinding or rewinding tension control systems that regulate torque by adjusting the current to ensure a constant tension during the winding process.

Use of Tape Slitting Machine:

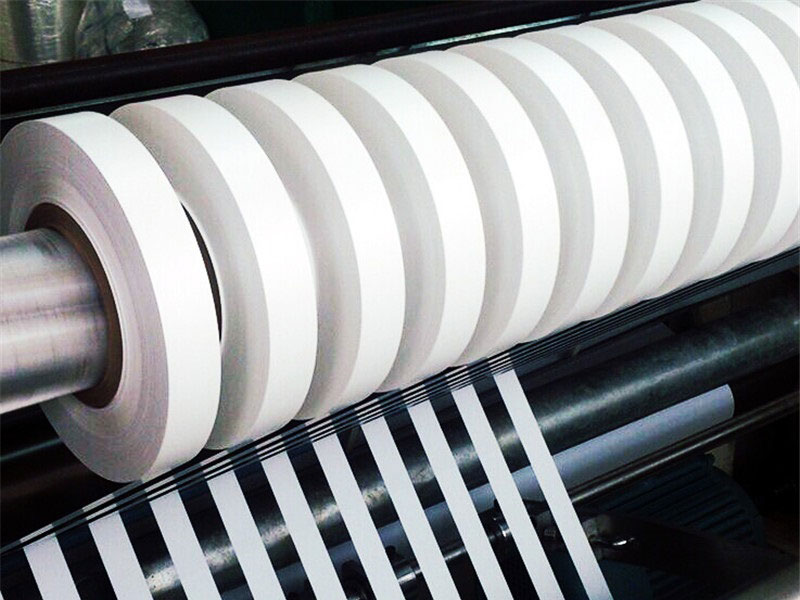

It is suitable for cutting BOPP, PVC, PE, masking paper, imported high-level double-sided tape, kraft paper tape, conductive foam plastic, cloth, industrial tape, protective film, etc.

Features of tape slitting machine:

It has automatic metering, counting, setting length, quantity automatic shutdown, automatic correction and unwinding control through photoelectric and other functions. The whole machine has compact structure, fast speed, high efficiency, accurate cutting, simple operation and stable operation.

Maintenance and maintenance of tape slitting machine:

Before use, the main parts of the automatic slitting machine should be inspected and lubricated with oil. When inspecting and disassembling the automatic slitting machine, it is strictly forbidden to use inappropriate tools and unscientific operation methods. Every two weeks, the machine will be cleaned and inspected. If the automatic slitter stops for a long time, all bright surfaces must be wiped clean, coated with anti-rust oil, and covered with a plastic sleeve for the entire machine. If the automatic slitting machine is out of service for more than 3 months, the anti-rust oil should be covered with moisture-proof paper. Once the work is complete, carefully clean the device, wipe down the exposed friction surfaces and add lubricant.

at the heart of the process of transforming huge master rolls into a dazzling array of small finished rolls, the tape slitting machine

18. October, 2025

it needs to be controlled from various aspects such as equipment adjustment, material selection, process parameter optimization, and operation specifications.

14. August, 2025

The following are the core advantages of single-sided adhesive slitting machines and their role in enhancing tape production:

12. August, 2025

Systematic optimization is carried out from multiple dimensions such as mechanical structure, control system, material science and human-computer interaction.

07. June, 2025

It improves production efficiency and is ideal for modern slitting production.

27. April, 2025