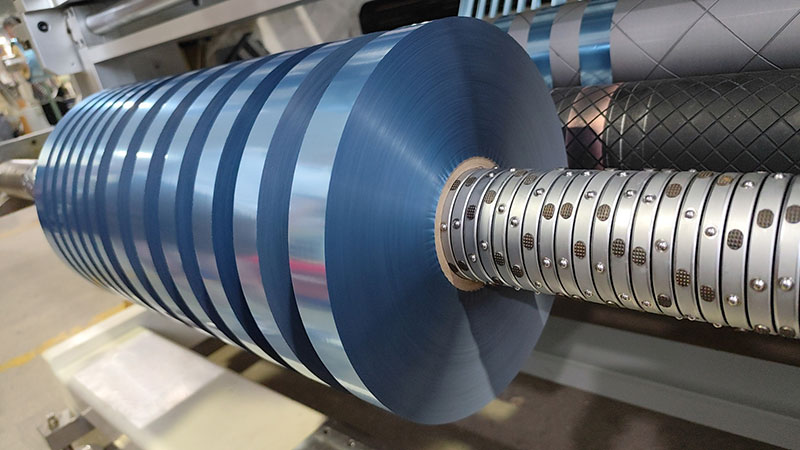

In modern manufacturing, high-precision slitting machine, as an important processing equipment, is widely used in various fields, such as electronics, optoelectronics, semiconductor and other industries. Its highly accurate cutting capabilities and stable performance provide reliable support for the manufacture and processing of products, driving the development of industrial technology.

Technical features:

1. Precision cutting: The high-precision slitting machine adopts advanced cutting technology, which can achieve precision cutting at the micron level, ensuring that the size and shape of the processed material meet the precise requirements.

2. Automatic control: The equipment is equipped with an advanced automatic control system, which can realize automatic feeding, positioning, cutting and unloading, reducing manual operation and improving production efficiency.

3. High-speed processing: The high-precision slitting machine can not only maintain the precise processing quality, but also achieve high-speed cutting under the premise of ensuring accuracy, which improves the production capacity.

4. Multi-functional application: The equipment is suitable for cutting a variety of materials, including metal, plastic, rubber, paper, etc., with a wide range of application fields.

Applications:

High-precision slitting machines have important applications in many fields, including but not limited to:

1. Electronics industry: It is used for cutting and processing electronic components, circuit boards, etc., to ensure that the size and shape of components are accurate.

2. Optoelectronic industry: In the manufacturing process of optical components, display screens, etc., the material is precisely cut.

3. Semiconductor manufacturing: It is used for the cutting and processing of semiconductor materials to ensure the precision and stability of the chip.

4. Materials research: In the field of scientific research, high-precision slitting machines can be used to prepare samples and support the study of material properties.

Future Prospects:

With the continuous advancement of manufacturing technology and the growing demand of industry, high-precision slitting machines will continue to play an important role in various fields. In the future, with the development of material science and processing technology, high-precision slitting machines are expected to achieve higher precision and greater production capacity, providing more reliable and efficient processing means for industrial production.

In the future, hot stamping foil slitting machines will continue to evolve towards deep intelligence and system integration.

06. February, 2026

With the emergence of high-precision hot stamping foil slitting machines, this industry pain point is being fundamentally solved.

30. December, 2025

In the hot stamping process, the slitting quality of hot stamping foil is a key factor affecting the loss rate, production efficiency, and final product quality.

26. September, 2025

In today's highly expensive and competitive manufacturing environment, any bit of material waste can directly eat into profits.

25. September, 2025

High-precision slitting is not just a simple narrowing of large coils of material, but a precision technology that integrates mechanical engineering, materials science and process control

19. September, 2025