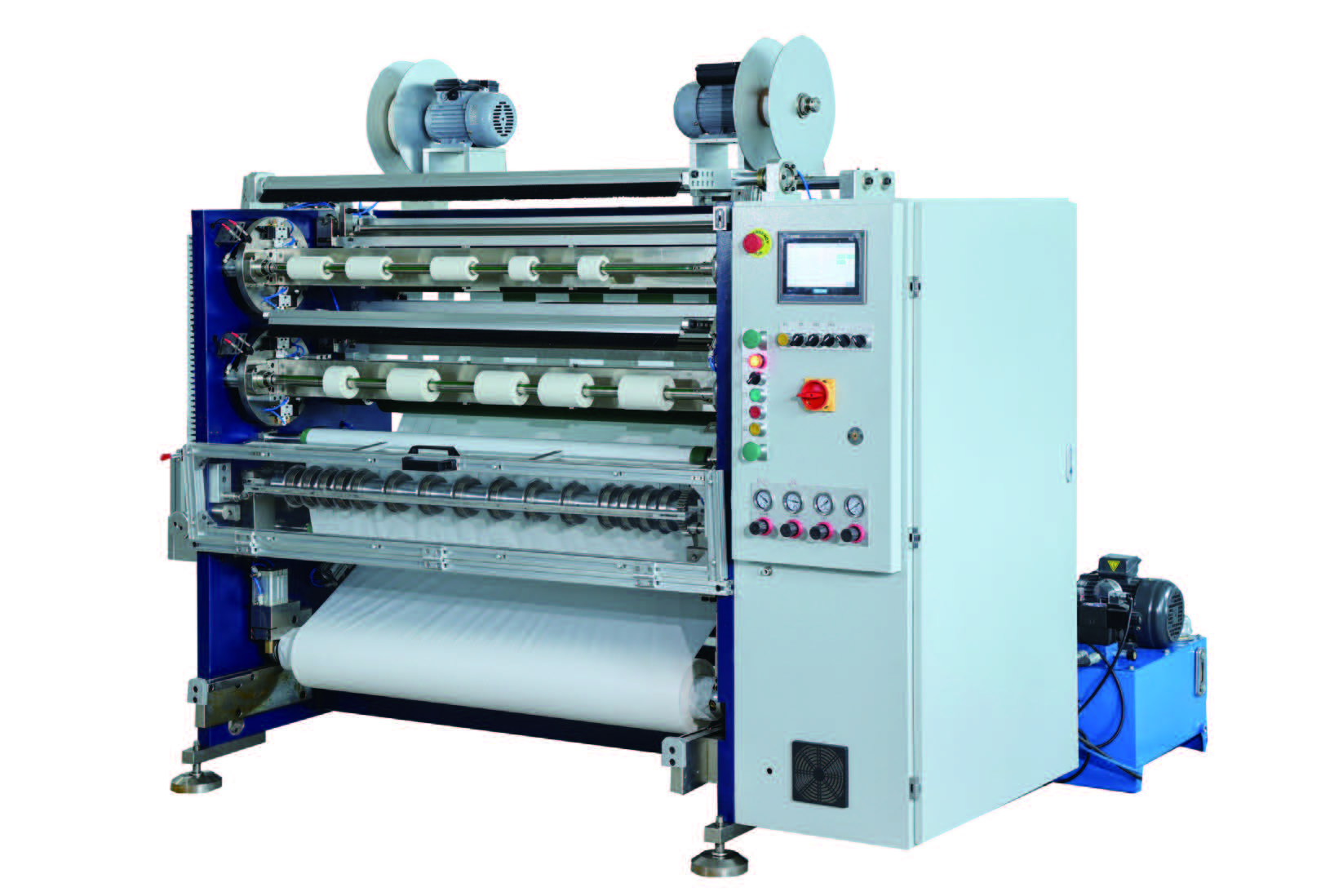

Improving product consistency is a critical requirement in tape manufacturing, and single-sided adhesive slitting machines are specialized equipment to achieve this goal. Through high-precision slitting technology, it ensures that the width, edge flatness, and coil tension of the tape are highly consistent, significantly improving product quality and professionalism. The following are the core advantages of single-sided adhesive slitting machines and their role in enhancing tape production:

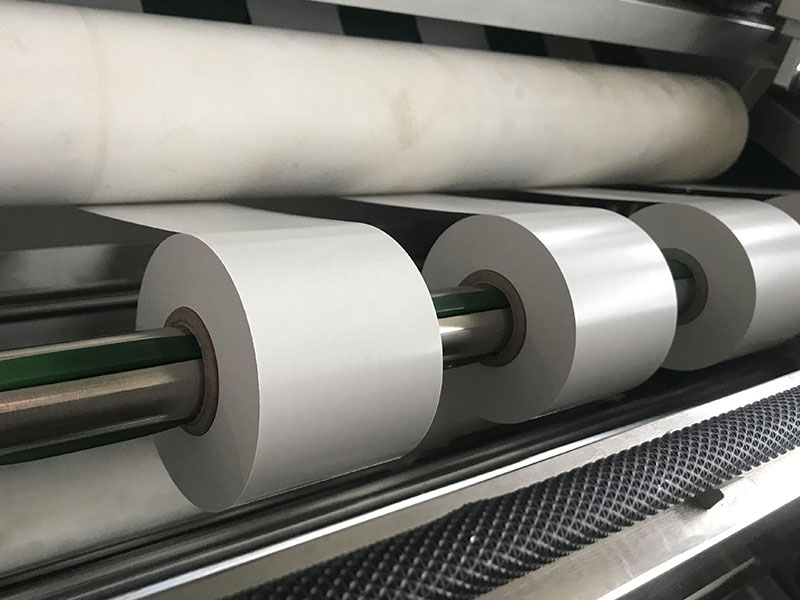

1. High-precision slitting to ensure dimensional consistency

• Precise control: Using CNC system or laser guidance technology, the slitting width error can be controlled within ±0.1mm, avoiding the deviation of traditional manual slitting.

• Edge Flatness: Sharp circular knife or ultrasonic cutting technology eliminates burrs, cracks, and other problems, improving the appearance and experience of the tape.

2. Stable tension control to avoid deformation of the coil

• Automatic tension system: adjusts the unwinding and unwinding tension in real time to prevent the tape from stretching and deforming or slackening, ensuring uniform thickness and consistent viscosity of each roll of tape.

• Adaptable to a wide range of materials: Whether it's PVC, BOPP, masking paper, or foam tape, it can maintain consistent slitting quality.

3. Automated operation to reduce human error

• One-click parameter setting: Quickly adjust the slitting specifications through the PLC touch screen, lowering the operating threshold and reducing the differences caused by human intervention.

• Online inspection function: CCD vision system can be optional to monitor the slitting quality in real time and automatically correct deviations to further improve the yield rate.

4. Improve production efficiency and reduce losses

• High-speed slitting: The maximum slitting speed can reach 300m/min (depending on the model) to meet the needs of large orders.

• Waste edge recycling design: Automatically rewind edge materials, reducing material waste and optimizing production costs.

5. Wide range of application scenarios

• Suitable for: industrial tapes, medical tapes, electronic tapes (such as PET release film), packaging tapes and other single-sided adhesive products.

• Customization options: Multi-tool slitting, dust extraction or static elimination can be configured according to requirements.

Why Choose a Professional Single-Sided Glue Slitting Machine?

• Customer pain point solution: Traditional slitting machines can easily lead to uneven tape edges and uneven coil tightness, affecting terminal use (such as wrinkled attachment and inaccurate die-cutting positioning).

• Enhanced brand value: High-quality tapes with strong consistency enhance customer trust and are suitable for industries with strict precision requirements (e.g., electronics, automotive).

Summary: Through precision mechanical design and intelligent control system, the single-sided adhesive slitting machine fundamentally solves the uniformity problem of tape slitting and helps you create more professional and competitive products in the market. If you need to know more about equipment selection or technical solutions, please provide your specific needs, and we will customize an efficient slitting solution for you!

it needs to be controlled from various aspects such as equipment adjustment, material selection, process parameter optimization, and operation specifications.

14. August, 2025

Providing a reliable solution for enterprises to reduce costs and increase efficiency.

09. August, 2025

In the field of industrial manufacturing, efficiency and precision are the core competitiveness of the production process.

08. August, 2025

Through automated and precise processing, production efficiency can be significantly improved and labor costs can be reduced.

06. August, 2025