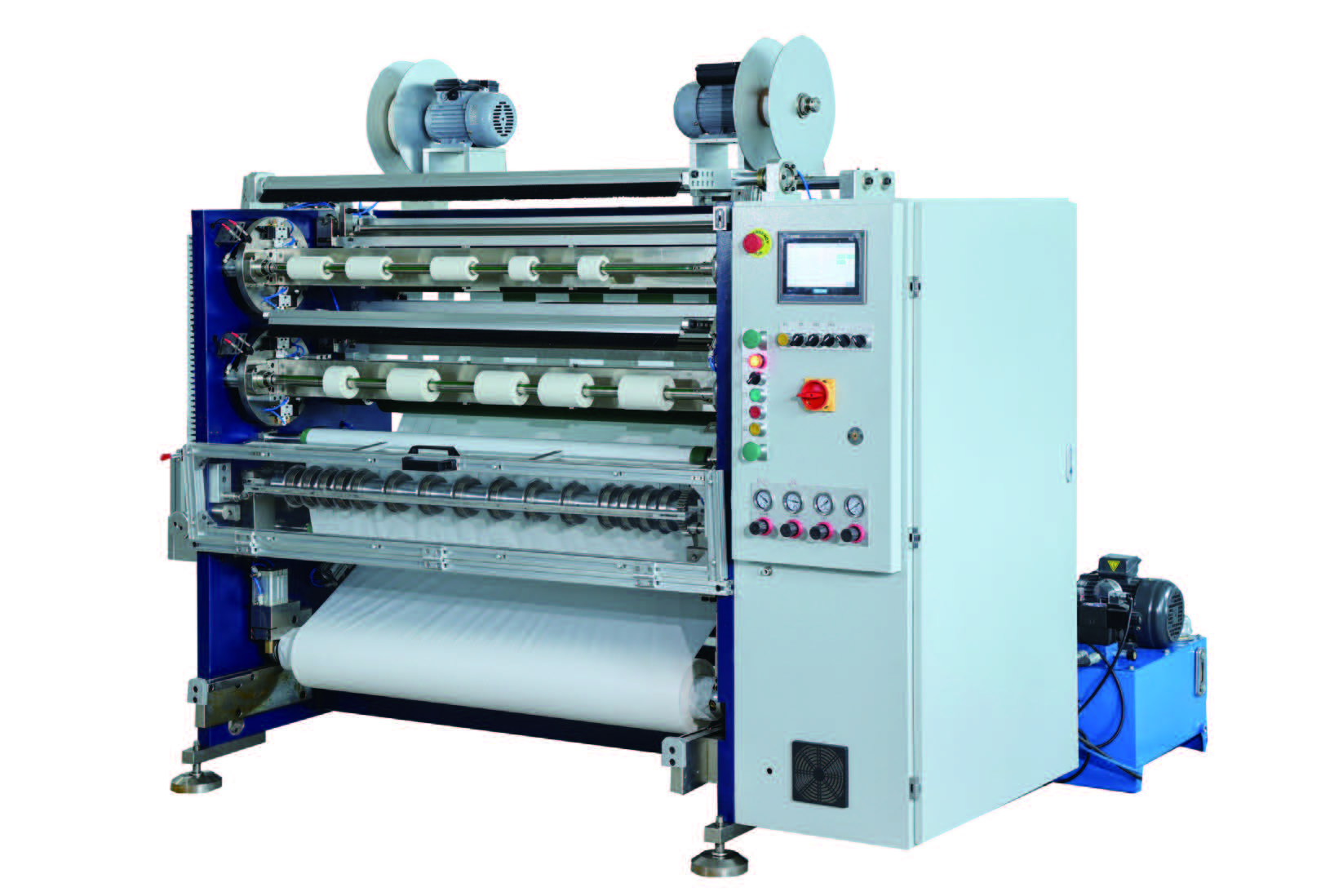

Through automated and precise processing, single-sided adhesive slitting machines can significantly improve production efficiency and reduce labor costs, and the following are their core advantages and specific applications:

1. Key points to improve production efficiency

• High-speed automated cutting

Single-sided adhesive slitting machines can achieve cutting speeds of tens or even hundreds of meters per minute (depending on the equipment model), which is much higher than manual operation, especially for large orders. For example, a standard slitting machine can process thousands of tapes per hour, increasing efficiency by up to 5-10 times.

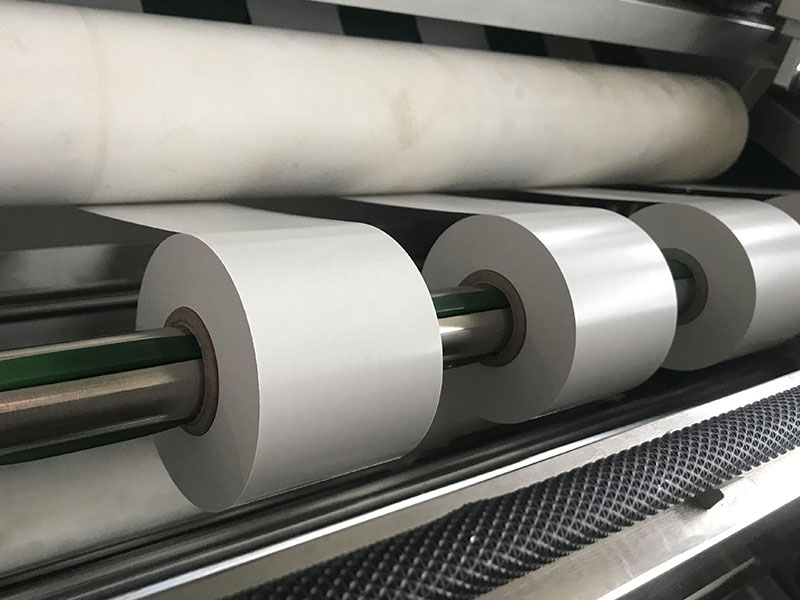

• Continuous operation capacity

The equipment supports automatic coil unwinding, slitting and winding, eliminating the need for frequent downtime and material change, reducing production interruption time. With automatic correction system, it can operate stably for a long time.

• Precise slitting reduces waste

Through CNC system or laser positioning, the slitting accuracy can reach ±0.1mm, avoiding the dimensional deviation of manual cutting and reducing material waste (such as the scrap rate caused by the edge burr of the tape can be reduced to less than 1%).

• Versatile adaptability

It can quickly switch between different widths and angles of slitting needs (such as bevel cutting and straight cutting), adapt to multi-variety orders, and reduce line changeover time.

2. Specific performance of reducing labor costs

• Reduce labor dependence

One slitting machine can replace 3-5 workers (based on an 8-hour shift), especially for high-precision or repetitive tasks, with significant labor cost savings.

• Reduce training and management costs

Operators can start with simple training without the need for skilled workers, reducing the impact of turnover.

• Reduce human error

Automated slitting avoids fatigue errors in manual operations (e.g., crooked cuts, uneven lengths), reducing rework and quality loss costs.

3. Other added value

• Energy saving and safety

Modern slitting machines use low-power motors and intelligent start-stop technology, reducing energy consumption by 20%-30% compared with traditional equipment; At the same time, the risk of workers coming into contact with knives is reduced.

• Data integration

Some models support MES system docking to monitor output, loss and other data in real time to optimize production planning.

Example of application scenarios

• Electronics industry: Precise cutting of mobile phone screen tape, replacing manual cutting.

• Packaging industry: batch processing of sealing tapes, improving efficiency and shortening the delivery cycle by 50%.

• Automotive manufacturing: Automated slitting of interior rubber strips to meet high consistency requirements.

Implementation recommendations

• When selecting equipment: match the model according to the material thickness and slitting accuracy requirements, such as the servo motor drive model is more suitable for high-precision scenarios.

• Maintenance Optimization: Regularly maintain tools and guides to maintain equipment stability and extend service life.

In the above ways, single-sided adhesive slitting machines can not only directly reduce production costs, but also indirectly enhance the ability of enterprises to receive orders by increasing production capacity and yield, especially suitable for labor-intensive or industries with high demand for tape processing.

it needs to be controlled from various aspects such as equipment adjustment, material selection, process parameter optimization, and operation specifications.

14. August, 2025

The following are the core advantages of single-sided adhesive slitting machines and their role in enhancing tape production:

12. August, 2025

Providing a reliable solution for enterprises to reduce costs and increase efficiency.

09. August, 2025

In the field of industrial manufacturing, efficiency and precision are the core competitiveness of the production process.

08. August, 2025