In the field of industrial manufacturing, efficiency and precision are the core competitiveness of the production process. With the rapid development of automation technology, traditional single-sided adhesive slitting machines are undergoing an intelligent transformation, through the integration of advanced control, machine vision and Internet of Things technology, to achieve comprehensive improvement in slitting efficiency and quality, and promote the upgrading of production models in industries such as tapes, labels, and films.

1. Core advantages of automated slitting

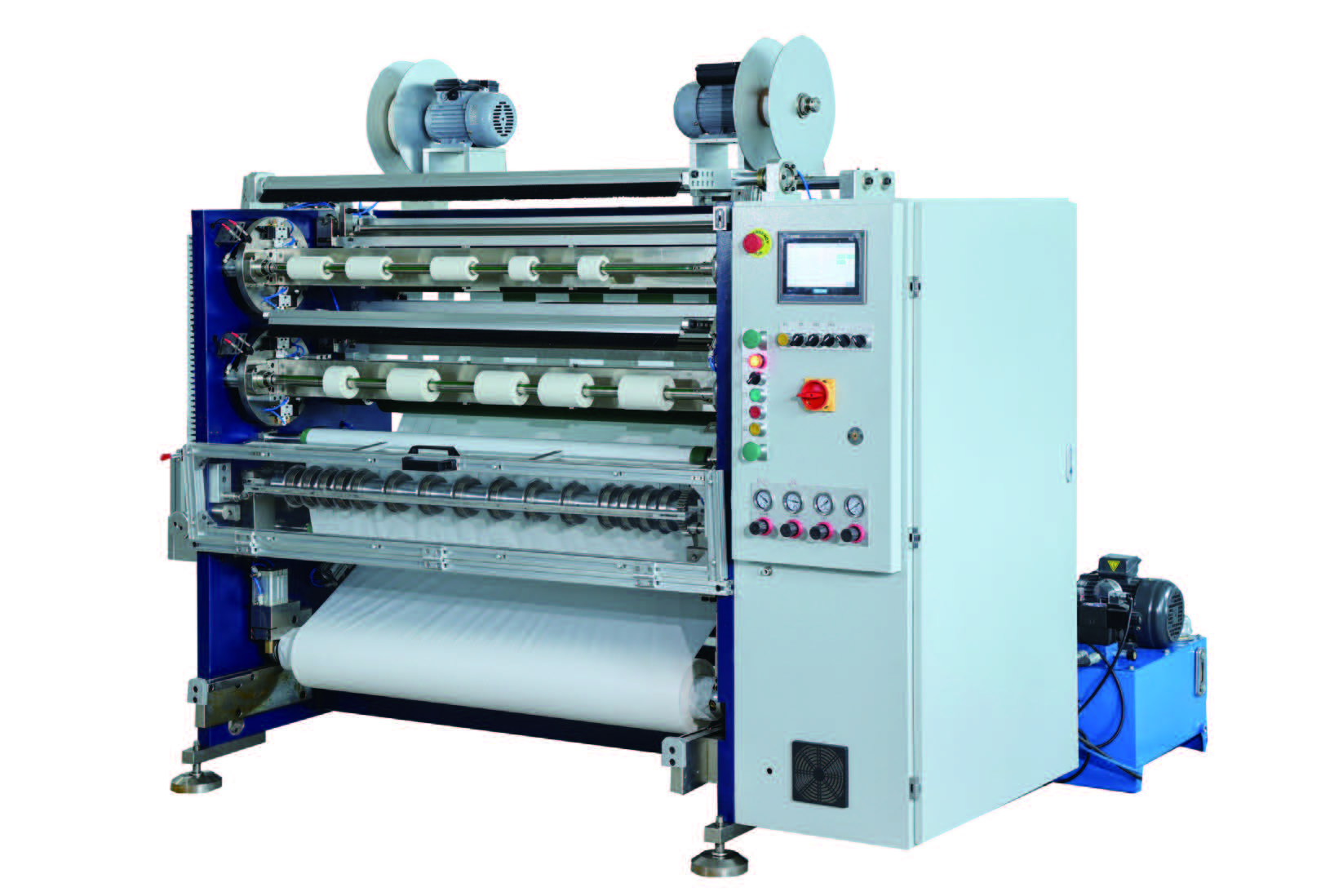

• High-precision cutting: With servo drive and dynamic correction system, the slitting width error can be controlled within ±0.1mm, suitable for ultra-thin or highly viscous materials.

• Intelligent production scheduling: Automatically adjust slitting parameters (speed, tension, tool spacing) through MES system to reduce manual intervention.

• Real-time quality inspection: Integrate AI visual inspection to automatically identify burrs, bubbles, stains and other defects, and realize the integration of slitting and quality inspection.

• Energy consumption optimization: intelligent algorithms dynamically adjust the power of the equipment, saving 15%-20% energy compared to traditional models.

2. Key technological breakthroughs

• Adaptive tension control: Magnetic powder brake and closed-loop feedback system ensure that the coil is free of tensile deformation during high-speed slitting (600m/min).

• Modular tool design: quick-change circular cutter/straight cutter combination, supporting multiple uses in one machine (such as slitting, cross-cutting, overlapping).

• Digital twin operations: Virtual models map equipment status in real time, and predictive maintenance reduces downtime.

3. Industry application scenarios

• Electronic tape: Accurately slitting high-value materials such as OCA optical adhesive and conductive adhesive to meet the stringent standards of consumer electronics.

• Pharmaceutical labeling: Achieve contactless slitting in a sterile environment to avoid the risk of contamination.

• New energy battery: There are no burrs on the edges when the ear rubber is slitted to ensure battery safety.

4. Future trends: from automation to intelligence

The next-generation slitting machine will deeply integrate 5G and edge computing, optimize global production capacity through cloud collaboration, and combine AR technology to achieve remote operation and maintenance guidance, further reduce manpower dependence, and create a benchmark for "black light factory".

epilogue

The automation revolution of single-sided rubber slitting machine is not only an upgrade of equipment, but also a transformation of production concepts. Through intelligent means, enterprises can respond to flexible production needs at lower costs and establish technical barriers in market segments. In the future, with the advancement of material science, slitting technology will continue to break through in the direction of ultra-precision and ultra-high speed, creating more possibilities for the manufacturing industry.

it needs to be controlled from various aspects such as equipment adjustment, material selection, process parameter optimization, and operation specifications.

14. August, 2025

The following are the core advantages of single-sided adhesive slitting machines and their role in enhancing tape production:

12. August, 2025

Providing a reliable solution for enterprises to reduce costs and increase efficiency.

09. August, 2025

Through automated and precise processing, production efficiency can be significantly improved and labor costs can be reduced.

06. August, 2025