Core economic values

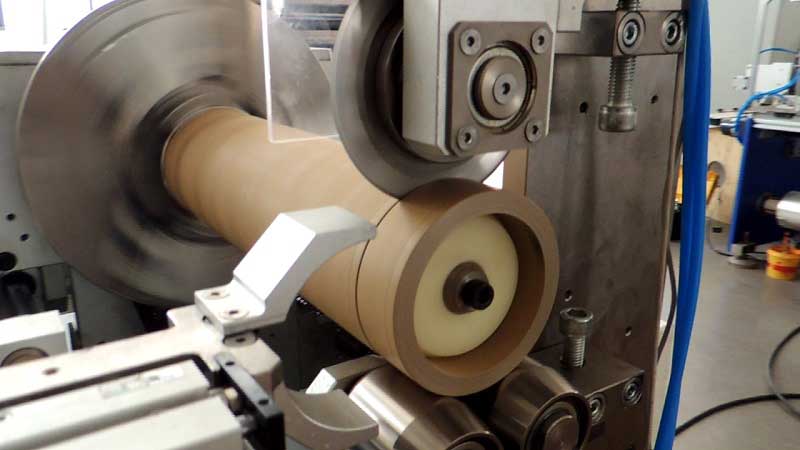

The paper tube cutting machine creates significant economic benefits for enterprises through precise cutting technology, mainly reflected in the following aspects:

1. Material saving

◦ Improved cutting accuracy can reduce raw material waste by 5-15%

◦ Optimized discharge design can improve material utilization by 8-20%

2. Improved production efficiency

◦ Automated cutting speed is 3-5 times faster than manual cutting

◦ Reduces mold change and adjustment time by 30-50%

3. Reduced labor costs

◦ Reduce reliance on skilled tradesmen

◦ A single machine can replace 2-3 workers

Return on investment analysis

Typical ROI cycle: 6-18 months (depending on production scale)

| project | The traditional way | Use a paper tube cutter | Improvement margin |

| Material utilization | 82% | 90-95% | +8-13% |

| Daily output (8 hours) | 800 pieces | 2400 pieces | +200% |

| Labor cost per piece | 0.8 yuan | 0.3 yuan | -62.5% |

| Scrap | 5% | 1% | -80% |

Long-term economic benefits

1. Improved quality consistency leads to increased customer satisfaction and fewer returns

2. Increased production flexibility to take on more diverse orders

3. Data-based production management provides a basis for continuous improvement

4. Equipment upgrade potential supports future capacity expansion

Implementation recommendations

1. Conduct a detailed production status assessment to determine the maximum waste point

2. Choose a paper tube cutting machine model that suits the product characteristics of the enterprise

3. Implement employee operation training

4. Establish a database of cutting parameters and continuously optimize settings

Through the scientific use of paper tube cutting machines, manufacturing enterprises can establish cost advantages in the highly competitive market, while enhancing the environmental protection image and achieving a win-win situation of economic and social benefits.

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025