Slitting machine is a kind of mechanical equipment that slits wide paper, mica tape or film into multiple narrow strips, and is commonly used in papermaking machinery, wire and cable mica tape and printing and packaging machinery.

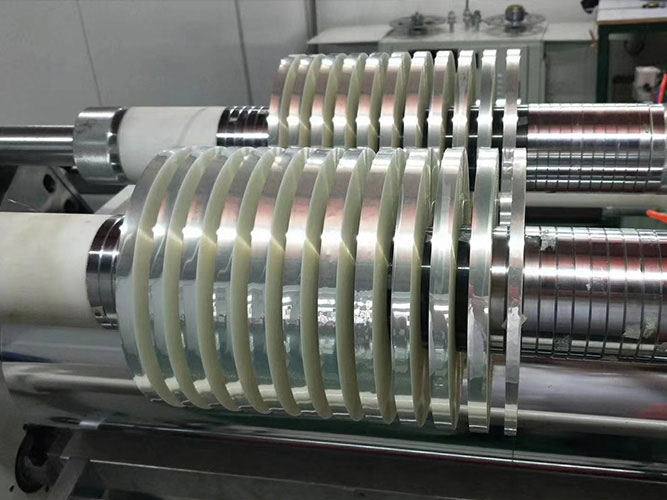

The slitting machine uses a knife to cut a certain width of coil longitudinally and cut it into several narrow coils. After installing it in a calender, extruder, gluing machine and other unit units, it can complete continuous strip cutting, often with a winding device. Strip cutters can be used with flat slice knives and round knives.

The speed of the slitting machine can not be high, and it is easy to cause high-speed friction of the magnetic particle during high-speed operation, resulting in high temperature, causing the magnetic particle clutch to heat up and shorten its life.

The slitting machine is mainly used in: non-woven fabrics, mica tape, paper, insulating materials and various film materials slitting, especially suitable for narrow strips (non-woven fabrics, paper, insulating materials, mica tape, film, etc.).

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026