Different slitting machine manufacturers, there will be differences in specific technical capabilities, when we are in the process of production, we should have a correct understanding and understanding of different slitting machine manufacturers, only when you can pay attention to more things and understand the specific situation, the following Xiaobian will take us to understand what are the common slitting methods of slitting machine blades?

1. Trimming: After a variety of materials are compounded, the process edge material is formed, and the product that meets the process requirements is obtained by cutting off the process edge material reserved in the process. This slitting method is mostly used in the processing of composite films and other materials.

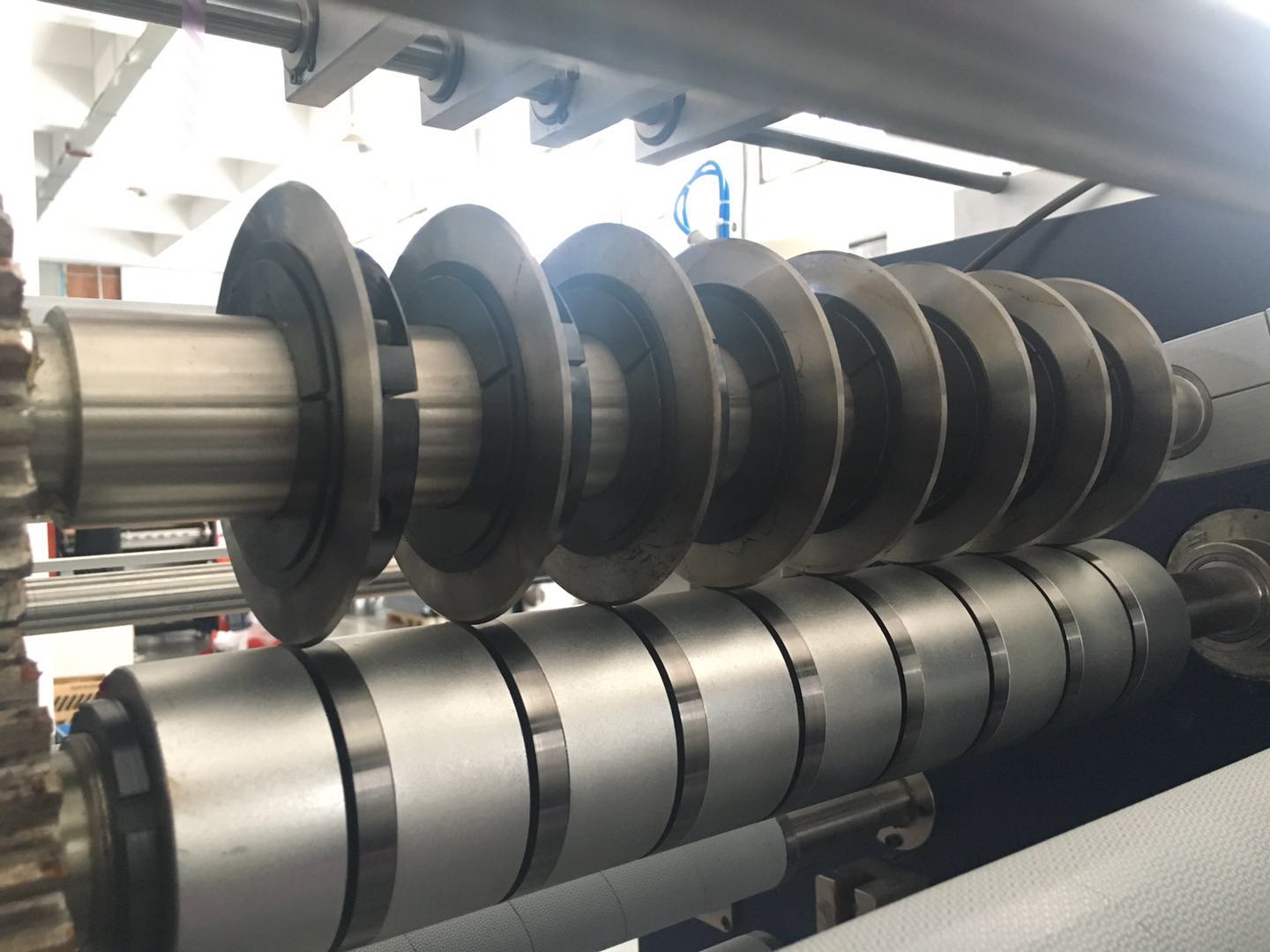

2. Cutting rolls: The whole roll of wide coils is divided into multiple rolls of narrow specifications through high-speed round knives. This slitting method is mostly used in the adhesive products industry.

3. Roll splitting: Divide the large roll diameter material into multiple rolls and small roll diameter materials according to the requirements of the winding length and width specifications. This slitting method is mostly used in the film substrate and flexible packaging color printing industry.

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026