The slitting machine is often used in the paper industry and the printing industry, because the speed of operation is relatively fast, and it is also one of the reasons why many factories choose it, the work efficiency will be improved, and the production material of the slitting machine is also a mystery. Let's talk about what material is the spindle of the slitting machine made of?

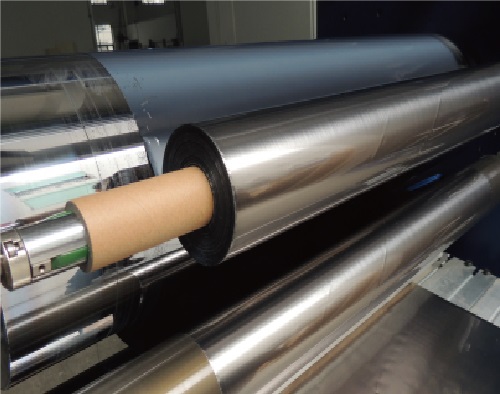

In addition to the material characteristics of slitting machine slitting on the spindle shaft surface material, in addition to the case that the rubber material is glued on the spindle, many of the materials to be slitted have anti-static, anti-scratch and other process requirements. In general, the materials of the spindle are: ordinary steel wheels (45# or above), embossing wheels, steel-clad granular tape, steel-clad cork tape, steel-clad Teflon tape, rubber wheels, mirror wheels, etc., in addition to the surface material, the spindle also needs to strictly control the diameter size tolerance, concentricity, straightness and other shape tolerances, special requirements of processing technology (such as rubber wheels need to add conductive powder, etc.), static balance correction, dynamic balance correction and so on.

Is the material slitted with or without glue, and the one that passes through the spindle is a positive rubber surface or a glued surface? If the main shaft is mounted on the positive rubber surface (that is, the glued and sticky side), the material of the spindle can be embossed and sprayed with Teflon and liquid silicone rubber.

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026

a sophisticated system that combines mechanical engineering, materials science, and intelligent control.

11. February, 2026

This article will comprehensively analyze the functional system of ribbon slitting machine and reveal how it achieves precise control from raw materials to finished products.

10. February, 2026

a machine that completes the three functions of slitting, rewinding and detection at the same time, and ribbon production ushers in an era of integrated intelligence.

10. February, 2026