In the process of paper operation, the paper slitting machine should also do a good job in the standardized operation, which is more standardized for the operation of the fixed length, but now many people do not know much about the fixed length specification, so let's talk about what is the fixed length specification of the paper slitting machine?

Fixed-length segmentation operations are divided into two types: static and dynamic segmentation: the device is accurately shut down when the length is set, and then the static data is segmented for production and processing, and the operation is restarted after segmentation; When the length of the setting arrives, the splitting data signal is not turned off, and the paper slitting machine dynamically divides the production and processing in the whole process of raw material fitness movement.

The key performance parameter of fixed-length segmentation is the segmentation precision, and the length of the finished product is consistent.

The length of the segment can be set continuously, and if there is a deviation in the specific length of the segment, it is very easy to correct it according to the method of setting the main parameters.

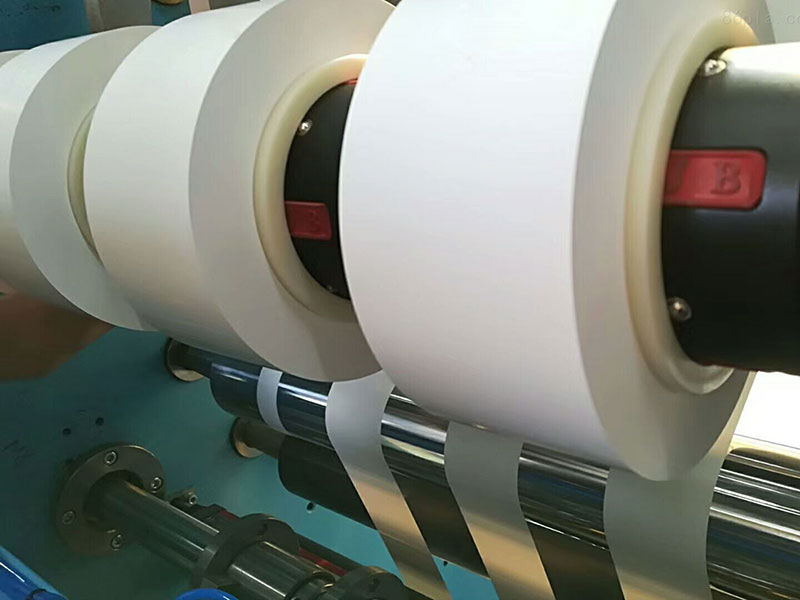

In order to carry out the production and processing of the whole roll or the whole raw material, such as plastic packaging materials, carton packaging, thick steel plates, films, leather products, wood, etc., it is necessary to use the fixed-length division operation of the paper slitting machine.

With the advancement of Industry 4.0, paper slitting machines are moving in the direction of smarter and more connected.

25. October, 2025

Before formulating a slitting plan, it is essential to fully understand the properties of each material and its impact on the slitting process.

23. September, 2025

Having advanced slitting equipment and technology is itself an endorsement of the strength of the enterprise.

23. September, 2025

After slitting, the physical state of the edge of the coil of hot stamping paper directly affects the subsequent processing and application.

23. September, 2025

As a key device for post-processing, the hot stamping paper slitting machine has seen a steady growth in market demand.

20. September, 2025