The use of slitting machine slitting effect is still very good, which for the attention of the knife or there are many, common precautions we still have to do a good job of understanding, let's talk about the next slitting machine for knife need to pay attention to what?

The process of cutting the cutter is not complicated, but it is necessary to first determine the difference between the end faces of the two cutter axes, and find the reference sleeve to fix it. Whether the effect of the slitting machine can be fully played out is also related to the way of the row knife, because of the lack of understanding we do not know how the row knife of the slitting machine, so we can not judge it.

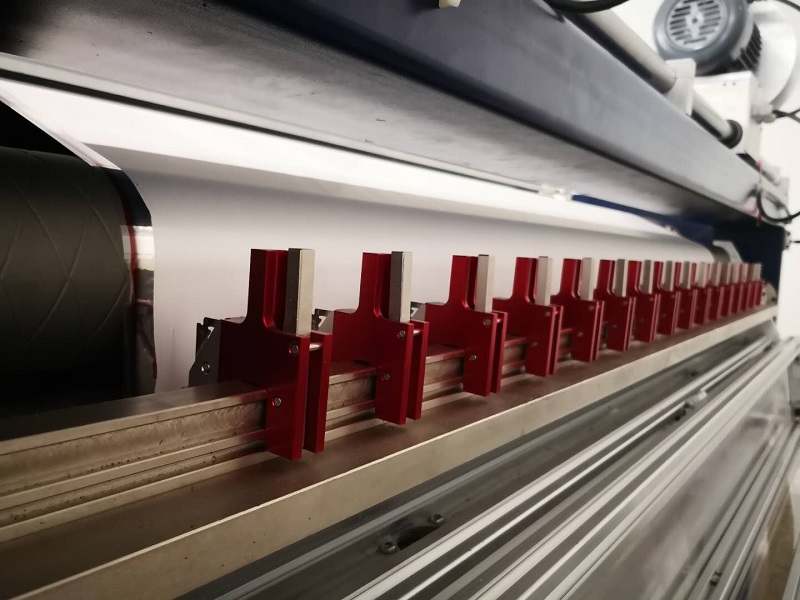

According to the cutting width row knife, generally the upper is the inner knife, the lower is the outer knife, that is, the left and right sides of the upper two knives are shear planes, and the inner sides of the lower two knives are shear planes. In addition to the position of the knife, the control of the knife gap is also very important, usually according to the thickness of the material as the base count, 0.5mm thick material gap in 0.03mm. In order to reduce the error, it is better to use a dial gauge when installing the knife to measure whether its beat is guaranteed within 0.01-0.02mm.

When the slitting machine rows, we should all pay more attention to the above rows of knives, and the correct rows of our slitting machine are what we all need.

It is not only production equipment, but also a key lever for enterprises to leverage profit growth by reducing costs, increasing efficiency and improving quality.

28. February, 2026

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026

Among them, slitting effect, winding quality and tension control are the three core elements that determine the yield.

26. February, 2026

traditional slitting equipment has become difficult to meet the market's stringent needs for efficiency, precision, and flexibility.

26. February, 2026

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026