Because the poor interface will cause quality problems such as broken film or wrinkle during the use of the film roll, which will cause a relatively bad impact on the user's use, the thin film interface must be operated in accordance with the regulations to ensure the bonding quality of the interface. The specific requirements are as follows:

1. Cut and flatten the two sections of the film of the joint horizontally, and paste it firmly on the front and back sides of the film;

2. In order to improve the quality of the interface, the film interface is required to be straight, balanced with the direction of the paper tube, and the interface is required to be flush without wavy, the interface at both ends is in the middle of the tape, try to avoid the size of the edge, and the adhesive tape is firmly attached to the film without obvious bubbles;

3. The membrane surface at the interface is required to be smooth and without obvious wrinkling;

With the help of automation technology, significantly reduce manual intervention and usher in a new phase of cost reduction and efficiency improvement.

28. February, 2026

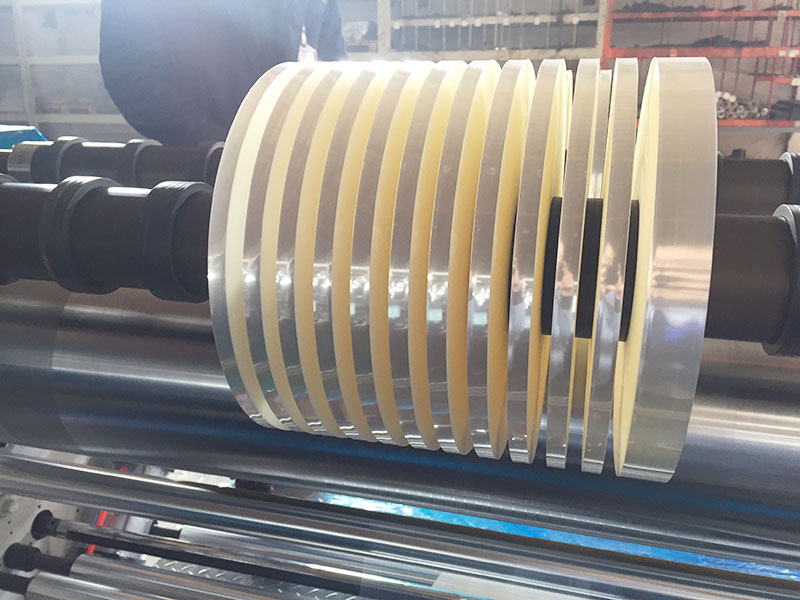

It is not just a simple "cutting", but a precision process of tension control, face neatness and winding quality.

27. February, 2026

Among them, slitting effect, winding quality and tension control are the three core elements that determine the yield.

26. February, 2026

traditional slitting equipment has become difficult to meet the market's stringent needs for efficiency, precision, and flexibility.

26. February, 2026

choosing a professional PET film slitting machine is no longer a luxury option but a necessity to remain competitive.

06. February, 2026