As an efficient and precise cutting equipment, the solar film slitting machine can significantly reduce material waste and improve production efficiency, becoming the "secret weapon" of enterprises to save costs. The following are the core reasons and implementation suggestions for saving 100,000 yuan in material costs per year:

First, the core advantages of solar film slitting machine

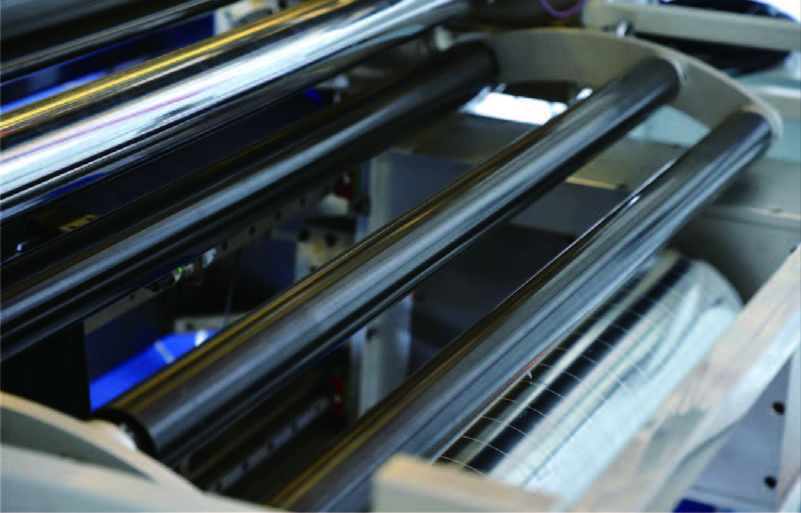

1. High-precision cutting

◦ Using laser or CNC technology, the cutting accuracy can reach ±0.1mm, avoiding the error of traditional manual or mechanical cutting and reducing edge waste.

◦ Supports special-shaped cutting (e.g., curved surfaces, hollowouts) to maximize material utilization.

2. Automated layout optimization

◦ Intelligent software automatically calculates the optimal nesting scheme to improve material utilization (up to more than 95%) and reduce leftover material loss.

3. Reduce human error

◦ Automatic operation avoids problems such as manual scratching and cutting, and reduces the defective product rate (can reduce waste by 5%~10%).

4. Efficient production

◦ The cutting speed is 3~5 times that of traditional equipment, shortening the delivery cycle and indirectly reducing warehousing and labor costs.

Second, quantitative analysis of cost savings

Assuming that the enterprise consumes 50,000 yuan of solar film raw materials per month, it can be achieved through the slitting machine:

• Material utilization rate increased by 10% → Save 5,000 yuan per month → 60,000 yuan per year

• Reduce the defective product rate by 5% → reduce the monthly loss by 2,500 yuan and save 30,000 yuan in → years

• Labor cost savings (1 operator reduction) → save 30,000~50,000 yuan per year

Total: easily exceed 100,000 yuan/year cost savings.

Third, key implementation suggestions

1. Select the adapter

◦ Select the slitting machine model based on parameters such as material thickness (such as building film, automotive film), coil width, and other parameters to ensure compatibility.

2. Training and process optimization

◦ Train employees to use typesetting software and develop standardized operating procedures (SOPs) to avoid waste caused by improper operation.

3. Regular maintenance

◦ Clean the blade/laser head and calibrate accuracy to maintain optimal equipment and extend service life.

4. Data monitoring

◦ Record the utilization rate and defect rate of each batch of materials, and continuously optimize the cutting scheme.

Fourth, industry application cases

• Automotive film enterprises: use the slitting machine to cut a roll of wide film into multi-specification products (such as car windows and car clothes), and the utilization rate is increased from 80% to 92%, saving 120,000 yuan in material costs per year.

• Architectural glass film supplier: intelligent typesetting reduces customized waste of special-shaped glass, and customer order response speed is increased by 30%.

Fifth, return on investment calculation

The price of a high-end solar film slitting machine is about 200,000~500,000 yuan, calculated by saving 100,000 yuan per year, and the cost can be recovered in 2~5 years, and the long-term benefits are remarkable.

Summary: Solar film slitting machine achieves "cost reduction and efficiency increase" through technological upgrading, which is a key tool for enterprises to enhance their competitiveness. Reasonable selection based on its own production needs, and focusing on personnel training and data optimization, can maximize its economic value.

This article will delve into how advanced automotive film slitting machines can help businesses achieve their goal of doubling production capacity.

04. February, 2026

These film materials need to be precisely cut into different widths during the production process to meet the needs of various models and components.

10. December, 2025

The automotive film slitting machine, an increasingly intelligent "cutting knife", is accurately cutting out redundant costs, inefficient processes and backward production methods.

10. December, 2025

It cuts wide raw film rolls into various sizes required by customers with millimeter-level accuracy.

02. December, 2025

What it completes is not only a physical form cutting, but also a profound value sublimation.

02. December, 2025