Aluminum foil slitting machine is a kind of mechanical equipment used to slitting and trimming aluminum foil materials. The main function is to divide the larger aluminum foil coil into the required aluminum foil strips with specific width and length through the cutting process. Aluminum foil slitting machines are widely used in industries such as food packaging, pharmaceutical packaging, electronics, and building materials.

The working principle of the aluminum foil slitting machine mainly includes steps such as coiling, unfolding, positioning, cutting and winding. Here's how it works:

1. Coiling: The aluminum foil slitting machine loads the aluminum foil coil into the machine by automatic or manual means, and adjusts the tension of the coil through the tension control system to keep it stable.

2. Unfolding: After the aluminum foil coil passes through the relaxation device, it enters the unfolding device, and the edge of the coil is unfolded through the tension adjustment system to maintain stability.

3. Positioning: The unfolded aluminum foil coil is positioned to the cutting position by adjusting the speed and tension of the conveyor belt through the tension guidance device.

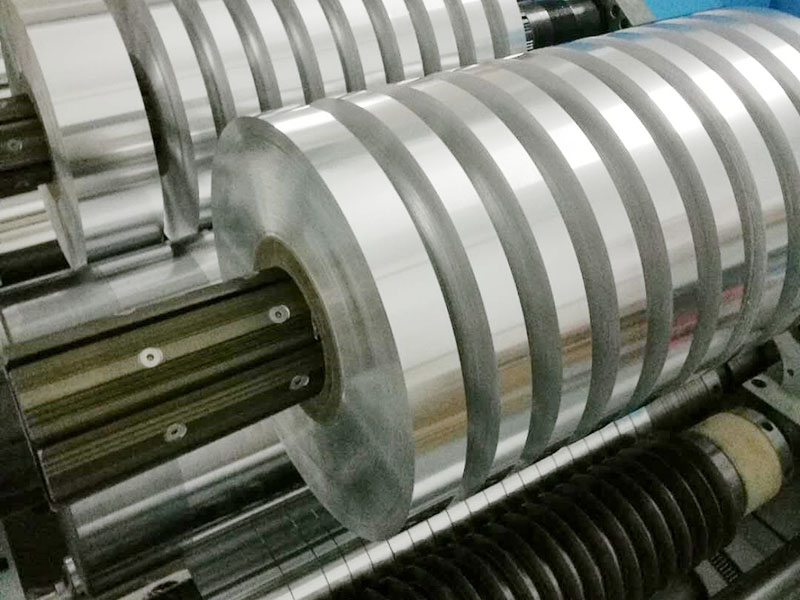

4. Cutting: After the aluminum foil coil is positioned to the cutting position, the knife system starts to work. Cutting is usually done with a round knife or a combination of multiple knives. The foil coil is cut by a knife system and divided into the desired strips of foil with a specific width and length.

5. Rewinding: The cut aluminum foil strips are rewound by the winding device to become finished aluminum foil rolls or aluminum foil strips. The winding device can adjust the tension of the coil to maintain the tightness and flatness of the coiling.

The aluminum foil slitting machine is composed of key components such as a coiling device, a unfolding device, a positioning device, a cutting device, and a winding device. Among them, the unfolding device and the positioning device ensure the stability and accurate positioning of the coil, and the cutting device adopts high-precision tools and cutting speed control system to ensure the precision and efficiency of cutting.

The aluminum foil slitting machine has the characteristics of high efficiency, precision and stability, which can meet the production needs of different industries. Through the application of automatic control system, the operation of the machine is simpler and safer, and the production efficiency and product quality are improved.

This is not only a simple process of turning a wide coil material into a narrow band, but also an ultimate dance of tension, precision and blade on the micron scale.

15. October, 2025

Here are the key technical points of multi-material slitting:

05. August, 2025

When processing aluminized PET film, the slitting machine with insufficient corrosion resistance may corrode the knife roller due to solvent residues, affecting the sealing performance.

05. June, 2025

The following are the core technologies and application solutions of slitting machine in metal foil processing:

09. May, 2025

The following is an in-depth analysis of its core technology, covering the key links of precise slitting and efficiency improvement:

26. March, 2025