Slitting machine and cross-cutting machine are both machines used to cut materials, but they have some differences in their working principles and application fields.

1. How it works:

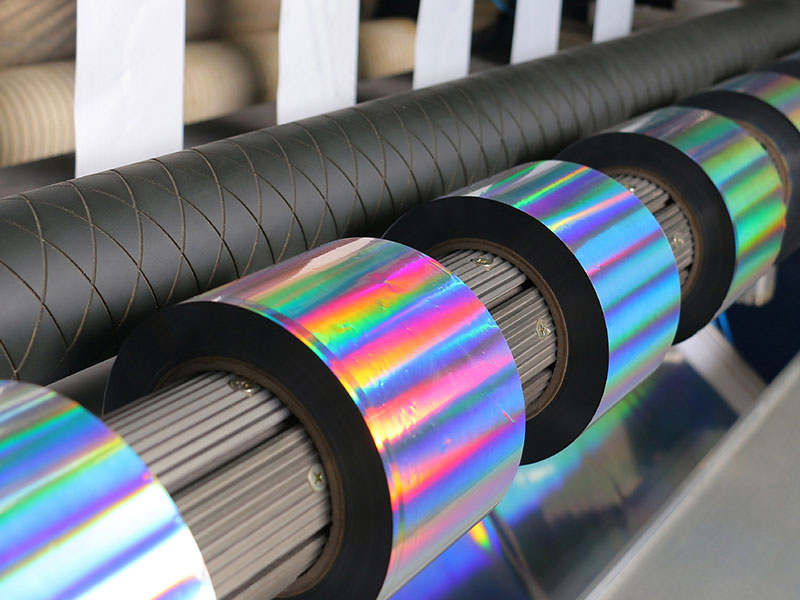

Slitter: A slitting machine is a machine that cuts materials from a wide large roll into narrow rolls, usually achieved by roller stretching and cutting mechanisms. The material is conveyed on the slitting machine, and after the action of the stretching and cutting mechanism, it is divided into narrow rolls.

Cross-cutting machine: A cross-cutting machine is a machine that cuts material from a wide large roll or sheet into short strips. This is usually achieved by means of conveyor belts and cutting mechanisms. The material is conveyed to the cutting mechanism via a conveyor belt and is cut to the desired length.

2. Applications:

Slitting machine: Slitting machine is mainly used in the processing industry of paper, plastic film, tape, fabric and other materials. It can cut wide raw materials into narrow rolls and is used in printing, packaging, bag making and other industries.

Cross-cutting machine: The cross-cutting machine is mainly used in the processing industry of wood, metal sheets, plastic plates and other materials. It can cut large rolls or large plates into the desired plates or strips and is used in industries such as furniture, construction, electronic equipment, etc.

In general, a slitting machine is to cut a wide material into a narrow coil, while a cross-cutting machine is to cut a wide material into short strips or plates. There are some differences in how they work and how they can be applied.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026