Explain some general operation precautions and usage instructions about the slitting machine. With the improvement of mechanization, the requirements for winding efficiency are getting higher and higher. In the cutting process of tape and tape, the whole roll can be cut into multiple small rolls according to different requirements to meet the needs of different occasions, and is widely used in the film cutting coating industry.

1. Application range of slitting machine:

1). The type of paper used for slitting, which is also the packaging market for mainstream products in packaging equipment at present.

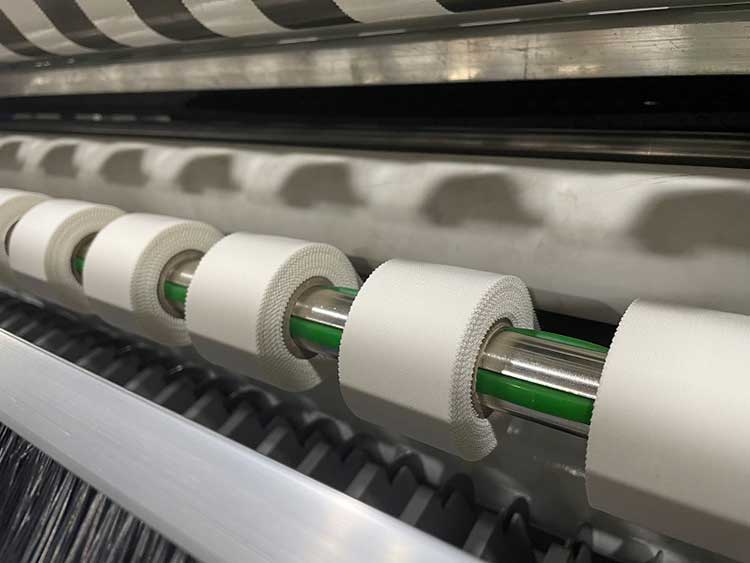

2). It is used in slitting leather, cloth, plastic, film and other industries.

3). Used for slitting metal coils, such as slitting strip steel, stainless steel, copper... It is mainly used in steel processing plants, pod steel market operators, steel rolling manufacturers, electrical industry, automobiles, stamping parts, etc.

2. Precautions for operation:

1). During use, you should pay attention to whether the parts are operating normally and whether there is any abnormal sound. Once it happens, it should be closed in time, find out the cause and eliminate it;

2). Ultrasonic correction, wear the material in manual mode before starting, and check whether the correction controller is automatic before starting.

3). Slowly accelerate when turning on the machine, and look at the upper and lower knives. The gap should not be too large, too large will have burrs, and too small will damage the cutter head.

4). When the school knife is put down, the distance between the upper knife and the lower knife is 2~3mm, lock the upper knife holder, aim at the middle of the lower knife groove, and then put down the upper knife holder to avoid the upper knife edge touching the lower knife. When calibrating the knife, the upper knife holder must be locked to prevent the upper knife holder from loosening, resulting in knife jumping during cutting.

5). Note: The machine should be grounded before use to prevent electric shock.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026