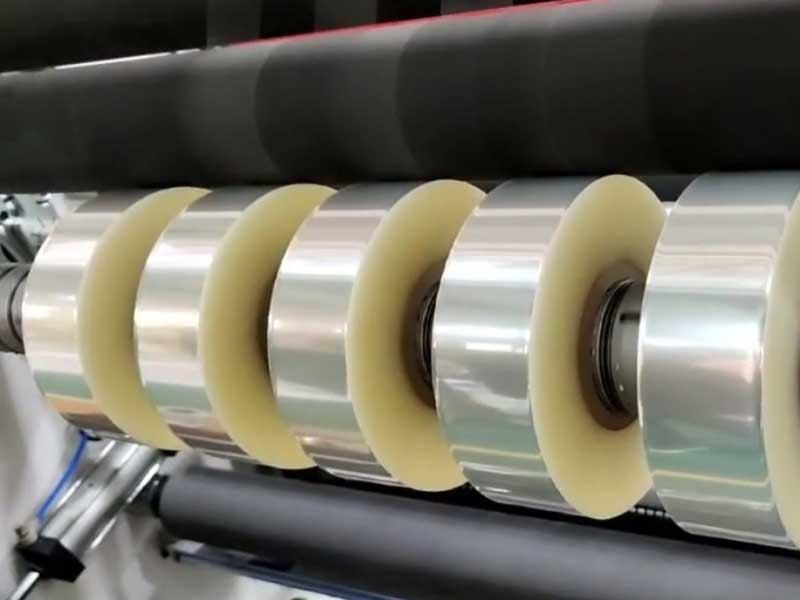

Slitters are very important equipment for the process industry, and they are used almost every day, and if they fail, they can hinder the production process and reduce production efficiency. Therefore, daily maintenance is a must, and the following points are summarized for reference, hoping to help you

First, the slitting machine is not evenly winded. Most of this situation is due to the fact that the paper core is not applicable, as long as the paper core that meets the required inner diameter is replaced, and the winding pressure roller is used in the winding process, the uneven winding of the slitting machine can also be avoided.

Second, the meter counting is not accurate. This kind of problem can be metered wheel, the two wheels at the same time contact the feeding rubber roller, and make a mark on the metering wheel, hand crank 5 times for the count, 1 meter, otherwise replace the meter.

Third, the trend of slitting and winding materials. This is mainly due to the incorrect winding tension, adjust the appropriate winding tension of the paper slitting machine, use a pressure roller for winding, and wrap the slitting material through the pressure roller before entering the winding paper core.

If the slitting machine is a band, then the tension control system is undoubtedly the conductor of the band.

02. March, 2026

What is the magic of this device that can conquer the discerning top manufacturers?

02. March, 2026

This paper will discuss the key path of PET film slitting machine upgrade from four dimensions: tension control, correction system, tool holder design and intelligent operation and maintenance.

02. March, 2026

What kind of slitting machine you choose determines to some extent how much you can release your production potential and how far you can go in the fierce market competition.

28. February, 2026

This article will delve into how ribbon slitting machines can protect the quality of barcode printing from the source.

28. February, 2026