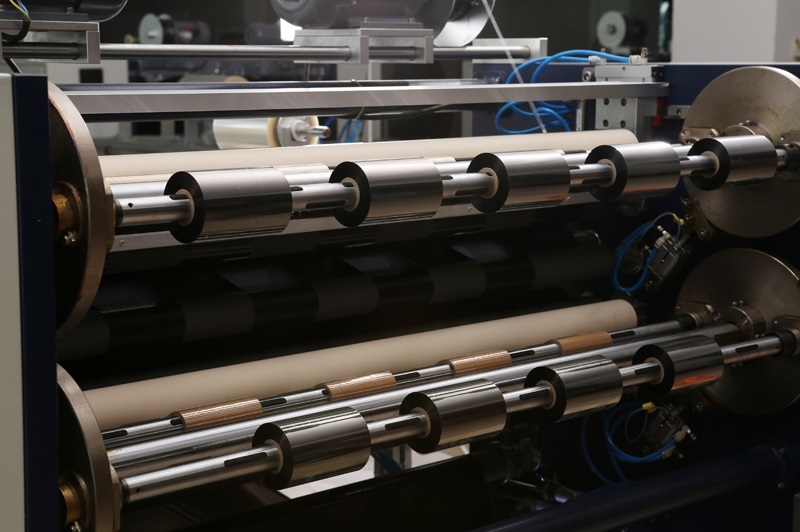

The effect of the slitting machine has been improving, and we also have a certain concern about its efficiency and capacity, and we have our own methods and skills for improving production capacity. The actual control value of the slitter tension remains constant.

Tension control of slitter unwinding: During the rewinding of a set of paper rolls, the rewinding tension should be avoided as much as possible to ensure that the winding tightness of the slitting rewinder is uniform inside and outside. Secondly, in the rewinding process of the slitting machine, if the tension control of the paper web is too small, the paper roll will be loose or slip on the bottom roller, resulting in wrinkles, paper interweaving and other paper problems.

If the tension control of the slitting machine is too large, it will cause the roll to burst or damage the paper core. Therefore, it is necessary to keep the actual control value of the tension constant during the rewinding operation of the paper web and to install a well-tuned inertia instantaneous compensation regulator in the tension closed-loop control system. The traditional control scheme of the slitting machine is to use a large motor to drive the shaft of the rewinding and unwinding, and a magnetic particle clutch is added to the rewinding and unwinding reel, and the resistance generated by it is controlled by adjusting the current of the magnetic particle clutch to control the tension on the surface of the material.

This article will comprehensively analyze the functional system of ribbon slitting machine and reveal how it achieves precise control from raw materials to finished products.

10. February, 2026

a machine that completes the three functions of slitting, rewinding and detection at the same time, and ribbon production ushers in an era of integrated intelligence.

10. February, 2026

From the large coil of raw material to the finished small coil in the hands of the end user, ribbon needs to go through a precise slitting process, which is the mission of ribbon slitting machines.

10. February, 2026

hot stamping foil slitting machine, which is silently promoting the precision and efficiency of the entire industry as an "expert in customized slitting solutions".

09. February, 2026

the new generation of hot stamping foil slitting machine is moving towards the goal of "zero waste and precise slitting" through a series of innovative technologies.

09. February, 2026