The slitting machine has been improving the effect of the slitting machine, we also have a certain concern about its efficiency and production capacity, and have our own methods and skills for increasing production capacity.

The linear pressure of the paper roller, the paper roller pressurizes the paper roll during the rewinding process, and in the initial stage of rewinding, the paper roller provides additional load on the paper roll, and acts together with the front and rear bottom rollers to provide a rewinding force for the paper roll. With the increase of the roll diameter, the position of the paper roller gradually rises, and the load provided by the paper roller also gradually decreases, when the roll diameter reaches a certain value, the load provided by the paper roller is zero, at this time, it exists only as a device to maintain the position of the paper roll The pressure control program of the paper roller must be selected according to the paper quality and the final diameter. In general, the clamping roller pressure is automatically controlled according to a pre-set pressure curve and does not need to be changed by the operator.

Tension control of unwinding: During the rewinding of a set of paper rolls, the rewinding tension should be avoided as much as possible to ensure that the winding tightness of the slitting rewinder is uniform inside and outside. Secondly, in the rewinding process, if the tension control of the paper web is too small, the paper roll will be loose or slip on the bottom roller, resulting in wrinkles, paper interweaving and other paper problems. If the tension is too large, it will cause the roll to burst or damage the paper core. Therefore, it is necessary to keep the actual control value of the tension constant during the rewinding operation of the paper web and to install a well-tuned inertia instantaneous compensation regulator in the tension closed-loop control system.

The leap in its core competitiveness stems from the comprehensive empowerment of intelligent control technology.

11. February, 2026

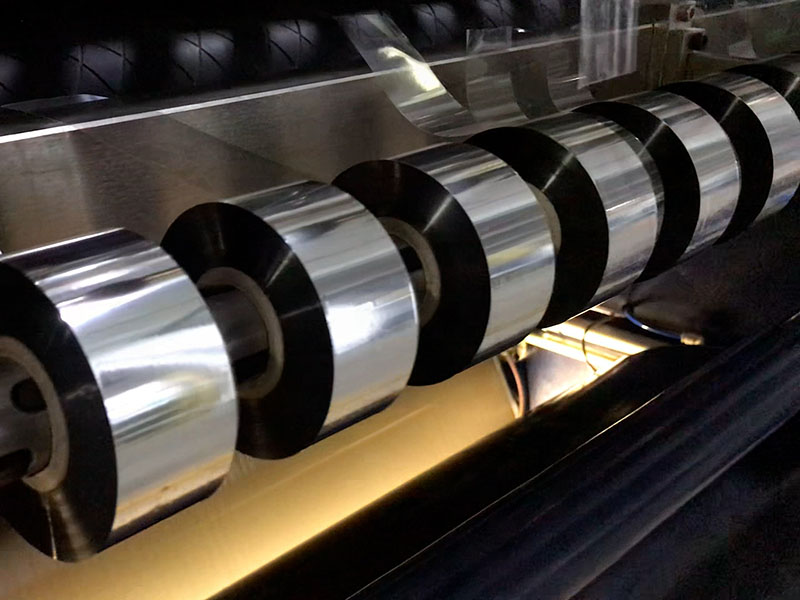

This article will delve into the design innovations and technological breakthroughs of modern hot stamping foil slitting machines in achieving high stability and durability.

11. February, 2026

a sophisticated system that combines mechanical engineering, materials science, and intelligent control.

11. February, 2026

This article will comprehensively analyze the functional system of ribbon slitting machine and reveal how it achieves precise control from raw materials to finished products.

10. February, 2026

a machine that completes the three functions of slitting, rewinding and detection at the same time, and ribbon production ushers in an era of integrated intelligence.

10. February, 2026